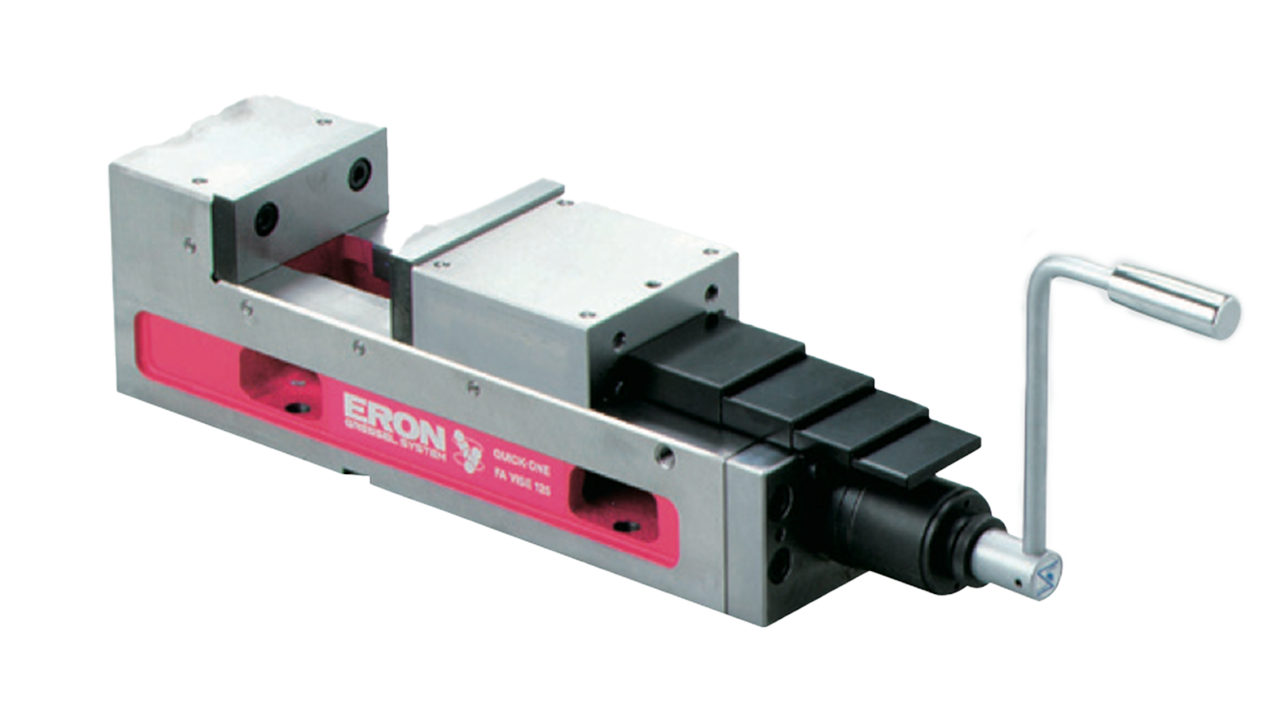

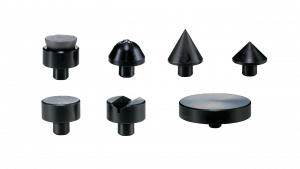

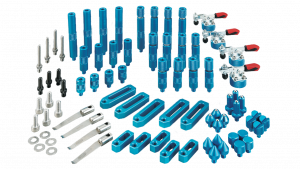

Parts Details

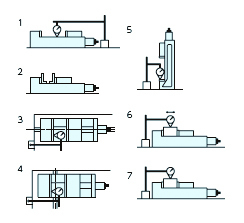

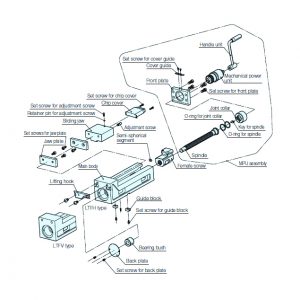

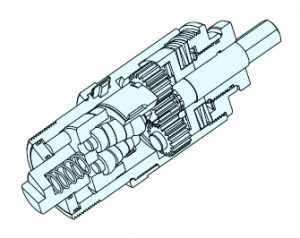

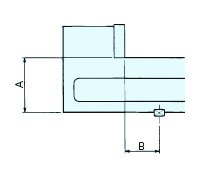

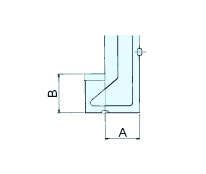

Section Drawing of the Mechanical Power Unit

*The shape around the handle insertion point differs in the LTFV-100Q.

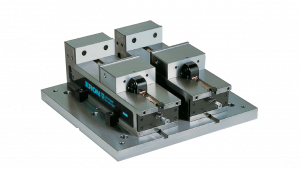

When ordering parallel products

(A and B align within 0.01 no matter how many pieces)

If the suffix of the manufacture no. (attached to the outer box and main body) is the same letter, then the products are parallel no matter how many pieces (for standard guide blocks). There is no charge for parallel products.

◆When purchasing for the first time

Order matched specification products (suffix G).

When ordering, specify the groove width of the machine you are using.

◆For additional orders

Contact us with the suffix letter of the manufacture no. of a vise that you have (stamped on the name plate).

LTFV type / LTFH type

Accuracy Standards (Static Accuracy)

| No. | Inspection Points (per 100 mm) | Former JIS Standard (O Grade) |

Nabeya SPEC |

| 1 | Parallelism between bottom surface of main body and sliding jaw | 0.015 | 0.010 |

| 2 | Perpendicularity between jaw plate and sliding jaw | 0.030 | 0.015 |

| 3 | Perpendicularity between T-slot and jaw plate surface of stationary jaw side. | 0.015 | 0.015 |

| 4 | Parallelism between T-slot and jaw plate surface of stationary jaw side. Applies to LTFV type. Applies to LTFH type. | 0.015 | 0.015 |

| 5 | Parallelism between the bottom surface of the main body and the jaw plate surface of stationary jaw side. | – | 0.015 |

| 6 | Parallelism between top surface of clamped test block and bottom surface of main body | 0.020 | 0.015 |

| 7 | Lift-up of top surface of clamped test block | 0.030 | 0.015 |