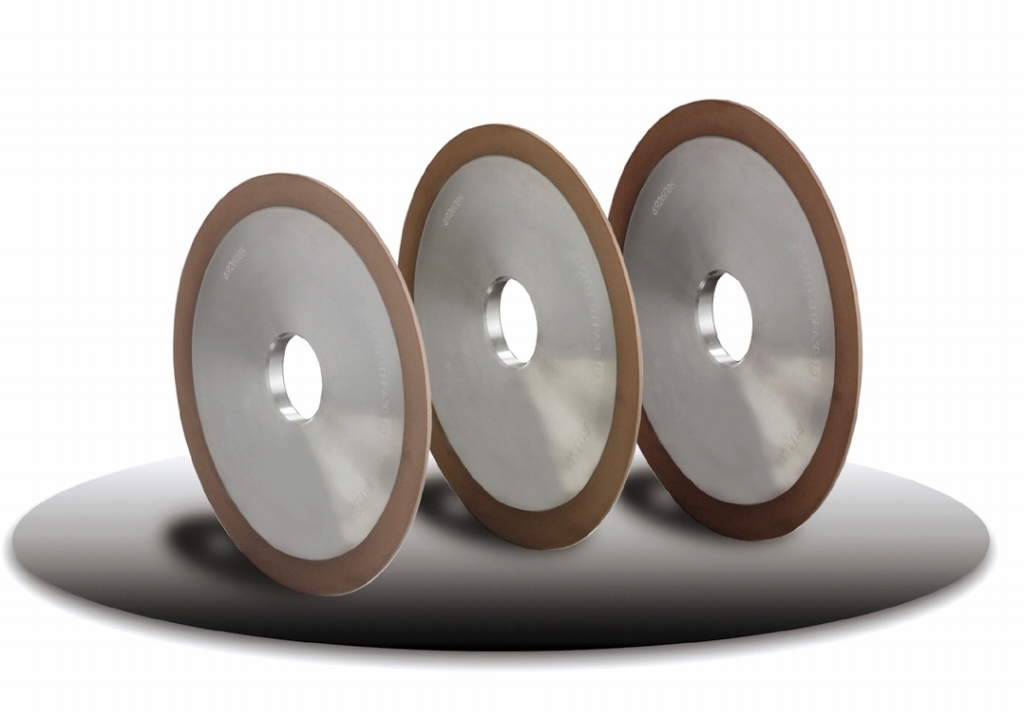

แสดงให้เห็นถึงประสิทธิภาพสูงในการเจียรหนัก

- โพลีอิไมด์เรซินมีความต้านทานความร้อนได้ดีที่สุดเมื่อเทียบกับเรซินทุกชนิด และใช้เป็นวัสดุใช้งานในการบินอวกาศ RESIACE เป็นล้อเรซินทนความร้อนสูงที่เพิ่มคุณสมบัติของเรซินโพลีอิไมด์ให้สูงสุด พวกมันแสดงให้เห็นถึงประสิทธิภาพที่สูงมากในการเจียรซึ่งมักจะทำให้เกิดการเสื่อมสภาพจากความร้อนด้วยการยึดติดเรซินแบบธรรมดา

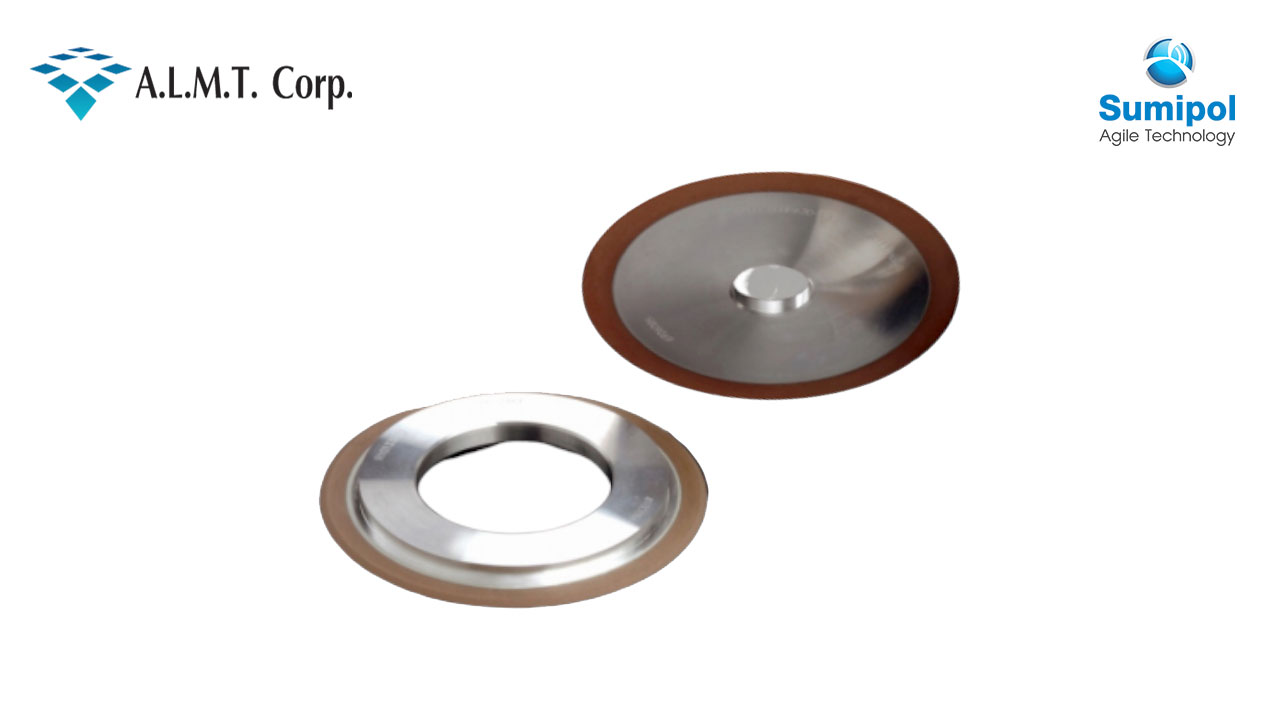

ลักษณะเฉพาะ

- ความต้านทานความร้อนที่สูงมากช่วยปกป้องพันธะจากการเสื่อมสภาพเนื่องจากความร้อนภายใต้สภาวะการบดที่รุนแรง เนื่องจากความคมที่ดีจะคงอยู่เป็นเวลานาน และช่วงการวัดรูปทรงจะขยายออกไป

- สามารถปรับปรุงประสิทธิภาพการบดและลดต้นทุนได้