Turning process is one of the important cutting processes. However, the tool wear is still the main problem in turning process because it deteriorates not only the machined surfaces quality but also geometry and accuracy. This finally causes the low productivity due to the interruption of the machining operation to change the new cutting tools.

Turning process is one of the important cutting processes. However, the tool wear is still the main problem in turning process because it deteriorates not only the machined surfaces quality but also geometry and accuracy. This finally causes the low productivity due to the interruption of the machining operation to change the new cutting tools.

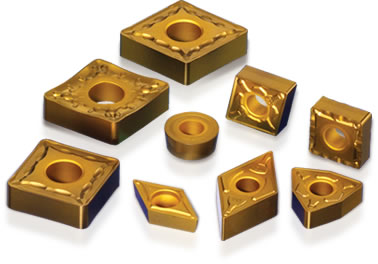

To cope with such challenges and obtain the accurate shape of the parts as required, Sumitomo Electric Hardmetal Corporation has newly developed a coated carbide turning tool grade “ACE COAT AC800P Series.

AC800P Series doubles the tool life and improves the reliability compared with conventional grades. To achieve such properties, thanks to an innovative technology by optimizing the originally developed Chemical Vapor Deposition (CVD) coating technology- “Super FF Coat,” by Sumitomo, which consists of titanium film with fine, smooth surface and alumina film with an accurately cemented carbide substrate.

By applying the new surface treatment technology to the AC800P Series, chippings and damages of cutting edges, which frequently cause problems during steel turning, are significantly reduced, preventing irregular wear and shortened tool life.

The three turning grades of AC800P Series include;

AC810P: a high wear resistance carbide coated grade for high speed and continuous turning of steel

AC820P: a general grade used for a wide range of steel turning from highly-efficient continuous machining to interrupted rough machining.

AC830P: exclusively for heavy machining and interrupted machining. With the coated carbide series including the three steel turning new grades, wide-ranging needs from manufacturers who wish to improve productivity and cost efficiency of steel turning will be perfectly fulfilled.