WHAT WE DO

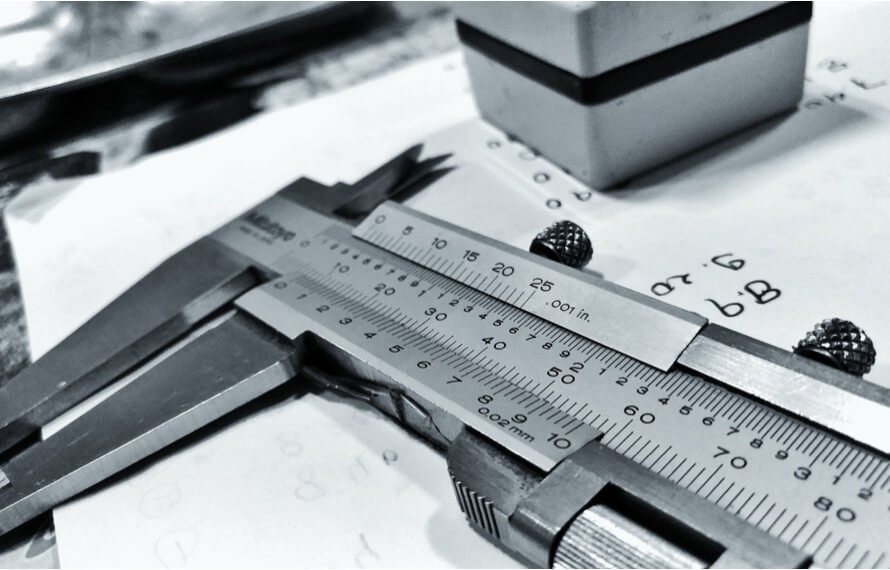

Calibration of measuring tools.

Calibrate your measuring tools according to international standards. In order to return the calibrated equipment to standard use again With the calibration of tools in the laboratory that has been certified by the standard system of the Thai Industrial Standards Institute.

Repair measuring equipment.

Repairing Mitutoyo measuring instruments by a process recognized by the manufacturer directly. For the unified standard of measuring equipment

New products are available.

If the measuring instrument shows distorted results Can not be used at full capacity We have new products for you to choose from. For smooth, uninterrupted work

International standard calibration process

Mitutoyo Measurement Instrument Repair Service, Free Initial Inspection

Sumipol’s calibration & repair service have a team of experienced Ready to service from initial inspection Calibration of measuring tools Repair measuring equipment Including offering quality tools For the best service

Why have to calibrate measuring equipment at Sumipol?

- Standard inspection equipment under the strict inspection laboratories Supervised by experts

- Provide consulting services on the use of measuring tools and maintenance methods Reading and interpreting data Principles of establishing acceptance criteria for tools

- Free transportation service for tools Within the service area

- For repair work There is a repair report for reference as well as guaranteeing the repair work for confidence in use.

Scope of calibration

| Item No. | Name of Measuring Tools | Range | Calibration Method |

| 1 | Micrometer caliper for External measurement | 0 mm to 300 mm | In – house method : WI (01) based on JIS B 7502 using gauge block |

| 2 | Depth micrometer | 0 mm to 150 mm | In – house method : WI (02) based on JIS B 7544 using depth micro checker and gauge block |

| 3 | Inside micrometer | 5 mm to 175 mm | In – house method : WI (03) based on JIS B 7502 using gauge block |

| 4 | Caliper (Vernier, dial, digital) | In – house method : WI (04) based on JIS B 7507 using gauge block / caliper checker | |

| – External | 0 mm to 1,000 mm | ||

| – Internal | 5 mm to 600 mm | ||

| – Depth | 0 mm to 300 mm | ||

| 5 | Height gauge | 0 mm to 600 mm | In – house method : WI (05) based on JIS B 7517 using gauge block / caliper checker |

| 6 | Dial gauge | 0 mm to 80 mm | In – house method : WI (06) based on JIS B 7503 using dial gauge tester / calibration tester / indicator tester (i-checker) |

| 7 | Dial test indicator | 0 mm to 1.6 mm | In – house method : WI (07) based on JIS B 7533 using dial gauge tester / calibration tester / indicator tester (i-checker) |

| 8 | Bore gauge | 6 mm to 250 mm | In – house method : WI (08) based on JIS B 7515 using dial gauge tester / indicator tester (i-checker) / ring gauge |

| 9 | Three point internal micrometer | 6 mm to 300 mm | In – house method : WI (09) using ring gauge |

| 10 | External caliper gauge | 0 mm to 50 mm | In – house method : WI (10) using gauge block |

| 11 | Internal caliper gauge | 2.5 mm to 120 mm | In – house method : WI (11) using gauge block |

| 12 | Thickness gauge | 0 mm to 20 mm | In – house method : WI (12) using gauge block |

| 13 | Feeler gauge | 0.01 mm to 1.0 mm | In – house method : WI (13) based on JIS B 7524 using digimatic indicator |

| 14 | Dial gauge tester, Micrometer head | 0 mm to 25 mm | In – house method : WI (14) based on JIS B 7502 using linear gauge |

| 15 | Linear gauge | 0 mm to 50 mm | In – house method : WI (15) based on JIS B 7503 using indicator tester (i-checker) |

| 16 | Bar-shaped micrometer calipers for internal measurement (tubular type) | 50 mm to 500 mm | In – house method : WI (16) based on JIS B 7502 using gauge block |

| 17 | Microindicator | 0.08 mm to 0.80 mm (Dial Reading) | In – house method : WI (18) based on JIS B 7519 using indicator tester (i-checker) |

| 18 | Roughness Tester (Portable) | Ra, Rz (Range Z-axis) 360 µm | In-house method : WI (19) based on ISO 12179 Geometrical Product Specitications (GPS) Surface texture : Profile method Calibration of contact (stylus) instruments |

| 19 | Can seam micrometer | 0 mm to 13 mm | In – house method (WI 21) using gauge block |

| 20 | Caliper Depth Gage | 0 mm to 300 mm | In – house method (WI 23) based on JIS B 7518 using gauge block |

Scope of calibration (On-site Service)

| Item No. | Name of Measuring Tools | Range | Calibration Method |

| 1 | Roughness Tester (Column) * | Ra, Rz, RSm (Range Z-axis) 800 µm | In-house method : WI (19) based on ISO 12179 Geometrical Product Specitications (GPS) Surface texture : Profile method Calibration of contact (stylus) instruments (On-site Service) |

| 2 | Profile projectors | 0 mm to 100 mm (X ,Y) >100 mm to 200 mm (X) | In – house method (WI 28) based on JIS B 7184 (On-site Service) |

| 3 | Surface plates | 300 mm to 2500 mm | In – house method (WI 30) based on JIS B 7513 using electronic level (On-site Service) |

| 4 | Measuring microscope | > 200 mm to 300 mm (X) | In – house method (WI 32) based on JIS B 7153 (On-site Service) |

| 5 | Rockwell hardness testing machine | Scale HRA, HRBW, HRC | ISO 6508-2 : 2015 and ASTM E18-16 Indirect method (On-site Service) |

| 6 | Vicker hardness testing machine * | Scale HV1, HV5, HV10 | ISO 6507-2 : 2018 and ASTM E92-17 Indirect method (On-site Service) |

Note * In the process of requesting certification from the Thai Industrial Standards Institute (TISI)