Hardness, weldability, chip adhesion, and poor heat conductivity are common problems in the machining of stainless steels and titanium alloys.

- Sharp cutting edge reduces work hardening.

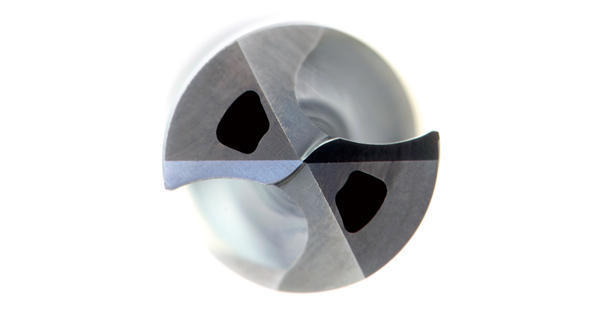

- New flute geometry enables the creation of compact cutting chips.

- Special margin shape reduces friction and heat generation.

- New coolant hole shape “MEGA COOLER” improves coolant flow, chip evacuation and cutting heat generation.

- WXL coating provides high adhesion strength, which minimizes the possibility of chipping.