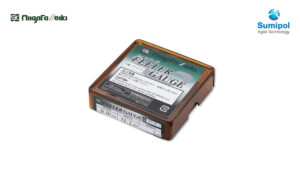

The objectives of the Standard Thread Gauge are

- Checking Accuracy: To verify if the thread has the correct dimensions and shape according to the standard.

- Quality Control: To control the quality of thread production.

- Machine Tuning: To assist in tuning the machines used in thread production to comply with standards.

Using the Standard Thread Gauge

- Measuring External Threads: Use the part with the moving thread into the specified slot of the gauge. If the thread passes smoothly, it indicates correct sizing.

- Measuring Internal Threads: Use the part of the gauge where the thread fits into the designated slot. If the thread passes smoothly, it indicates correct sizing.

- Using Go/No-Go: Gauges often have two sides, Go and No-Go. Use the Go side to check for acceptable sizing and the No-Go side to check for unacceptable sizing.

Maintenance and Care

- Keep the gauge clean to prevent wear and tear.

- Store the gauge in a dry and moisture-free environment.

- Regularly inspect the gauge to ensure it remains accurate