Double-sided contact tooling system Polygon Taper

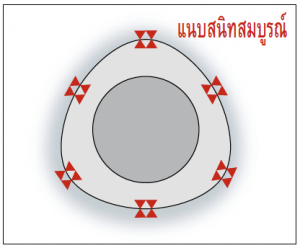

Double-sided contact system, 1/20 taper, triangular shape Developed by Sandvik Coromant AG in 1989, Daishowa Seiki began production under a licensing contract in 2000. While turning The polygon taper ensures a close contact throughout. This makes it a complete system that does not create a tolerance in the direction of rotation. The ISO standard was adopted in November 2008.

Double-sided contact system, 1/20 taper, triangular shape Developed by Sandvik Coromant AG in 1989, Daishowa Seiki began production under a licensing contract in 2000. While turning The polygon taper ensures a close contact throughout. This makes it a complete system that does not create a tolerance in the direction of rotation. The ISO standard was adopted in November 2008.

Outstanding difference in cutting edge when repeated measurements

Gapless polygon tapers act as drives for high-precision transitions.

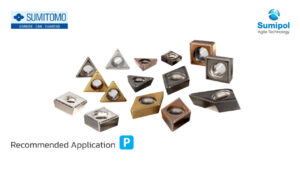

Series of turning knives for lathes and milling machines

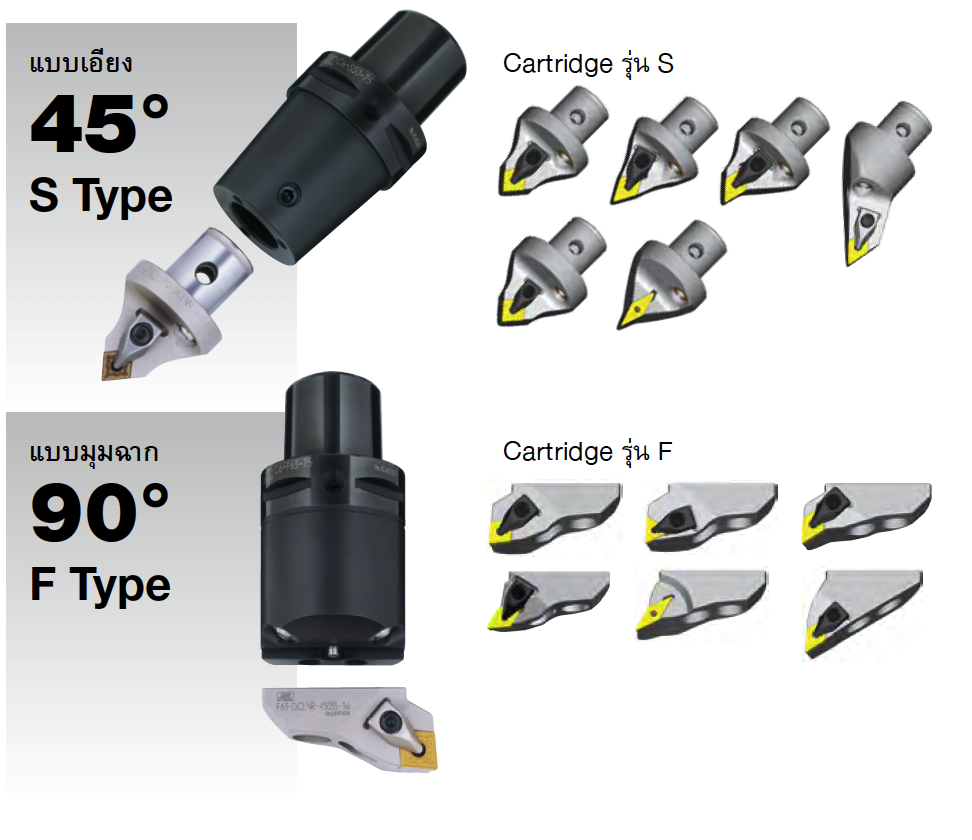

Cartridge variations and the introduction of modular systems Improves turning efficiency for milling lathes.

Various rotating tool series

- Collet chucks, MILLING CHUCKs, boring chucks, tap chucks, sensors, insert end mills, knife arms…many rotating tool chucks are available.