3D Metrology Target Markets

- FARO products focus primarily, but not exclusively, on segments of the 3D

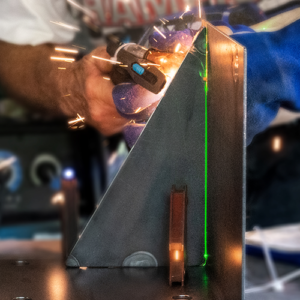

- Manufacturing industry which produce for, or supply to these sectors: Automotive, Aerospace/Defense, Metal Working

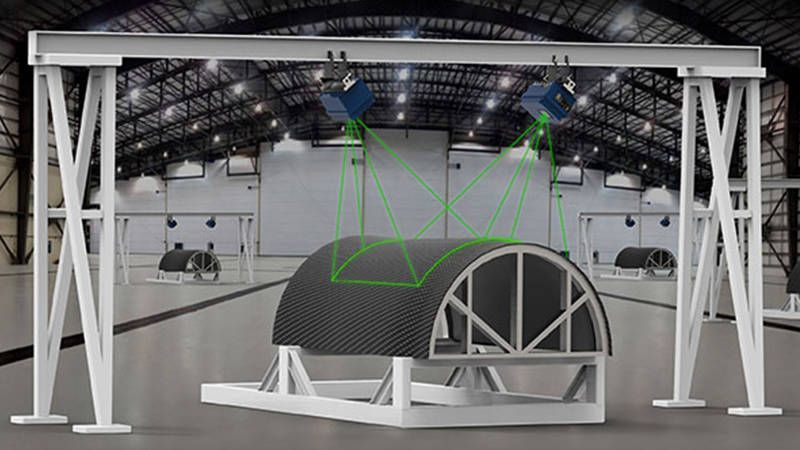

Features Common to TracerSI and TracerM Projectors

- 3D CAD-based Virtual Templating : Use virtual templating in a variety of manufacturing applications.

- Exceptional Projection Accuracy : Project with accuracy of 0.25 mm (0.010 in.) at 4.6 m (15 ft.).

- Workflow Automation : Use Tracer Laser Projectors with BuildIT Metrology Software and BuildIT Projector Software to automate workflow.

- Long-range Projection : Achieve accurate, variable and long-range projection (up to 15.2 m).

- Advanced Trajectory Control (ATC) : Ensure fast projection, superior dynamic accuracy and rapid refresh with minimized flicker.

- Multi-projector Array : Operate several laser projectors from a single workstation; ideal for large assemblies and space-constrained areas.

- Rugged, Reliable Design : Work with the protection of the device’s dust-sealed industrial enclosure and active thermal management.