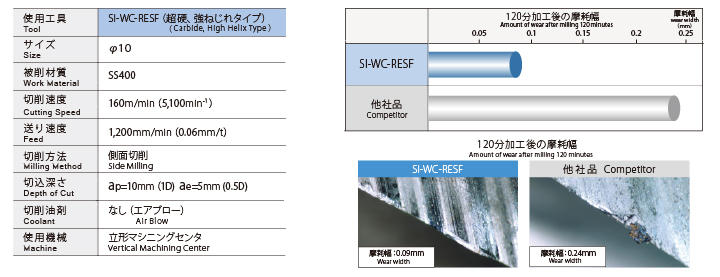

- Variable-lead geometry suppresses vibration.

- Enables low cutting resistance.

- WXL coating for long tool life in a wide range of materials and machining environments.

- Comprehensive lineup to accommodate various applications.

- OSG Silent Roughing end mills feature a ribbed edge that acts as a mechanical chipbreaker, shortening the chip and making it easier to handle. They are typically used in roughing operations with deep depths of cut and low horsepower machines.