The automotive industry in Thailand has shown robust growth since the 4th quarter in last year after being distracted by the economic turmoil worldwide. It has been successful in retaining its position as the “Detroit of Asia” as currently it is the 3rd largest industry in Thailand. More cars, automotive parts and accessories exports generate the 2nd biggest revenues for Thailand. Blue Update has insightful information indicating the prominent trends of automotive manufacturing towards 2011 and beyond.

Domestic Sales:

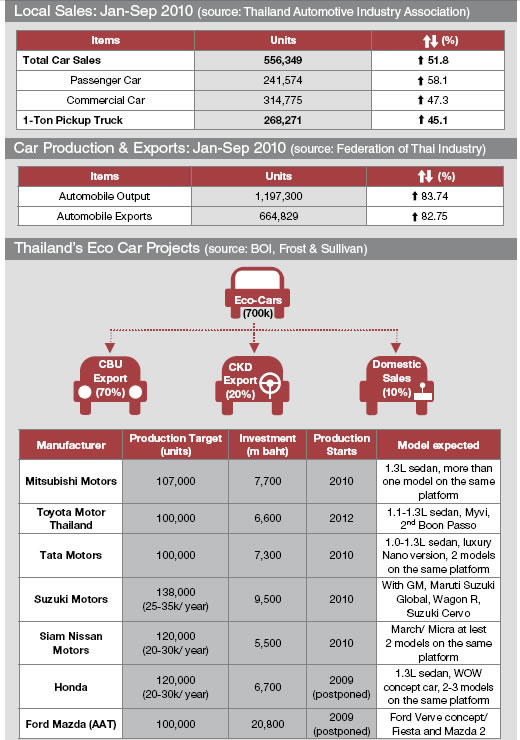

Thai Automotive Industry Association (TAI) announced a bounce in domestic demand. The accumulated numbers of total car sales in Thailand during January to September was 556,349 units, increased 51.8% from the same period last year. Only passenger car, in three quarters increased 58.1% to 241,574 units, further proving the fact that it is indeed Southeast Asia’s biggest car market. Meanwhile the commercial vehicle sales also boosted 47.3% to 314,775 units. 1-ton pickup truck (included modified pickup) increased 45.1% or 268,271 units. Thailand is regarded as the 2nd largest pickup market worldwide and also ASEAN’s largest automotive market and assembler. The remarkable growth in domestic sales is due in part to the reduction in excise duties for small passenger cars. This reduced the price of cars and the added advantage of credit availability was instrumental in increasing demand. In Thailand, both the passenger car market and pickup truck market are led by Toyota and Isuzu, together holding around 65 percent of the vehicle market and other key players are Mitsubishi, Nissan, Chevrolet, Ford and Mazda. Diesel powered passenger cars are also in vogue with Toyota in the leading position followed by Honda for market share.

Export Sales:

Export Sales:

The automotive and auto parts industry was responsible for a huge increase in export revenue less than only that of computer and electronic parts. This contributed considerably towards the nation’s GDP. According to the Federation of Thai Industries, automobiles export from Thailand is witnessing upward growth. Especially, the demand for Thai-made one-ton pickup trucks grew in demand both in the domestic as well as export markets. When looking overall in the first nine months to September, car exports were up to 664,829 units or increased 82.75% compared to the same period last year. Thailand became an automotive hub in Asia Pacific with many supporting factors. With a highly developed level of infrastructure and proximity to Southeast Asia’s largest Thailand is a natural logistics hub. Geographically, Thailand is located closer to the heart of Asia than any Asian cities, this is an incredibly important factor when considering transportation costs, time to delivery of goods and access to supply and distribution networks. Moreover, benefits derived from the free trade agreements signed with ASEAN countries, Australia, New Zealand, China and India and so on are a driving factor in an increase of automobile exports from Thailand. Especially, the ASEAN countries are major export market destinations after Europe, Australia and middle-east.

Production Output:

Production Output:

The car production output from January till September was 1,197,300 units- an increase of 83.74% on the same period last year. According to TAI, the car production in Thailand in this year is estimated at 1.65 million units if the economy is stable and the currency is not too volatile. As for next year- 2011, the best case scenario is foreseen that the automobile production might hit 1.8 million units, given planned introduction of many new models and the upcoming eco-cars. At the same time, new project that Thai government is trying to promote as the “Best Little Car” project. TAI also looks at a long-term future after pickup trucks, and eco-cars which are current flagship projects of the country, there might be a third pillar such as luxury cars or electric cars, where Thailand could be a base for production within the region.

Auto Parts and Components

The automobile parts manufacturing sector in Thailand is respected as the best in South East Asia, according to Japan Automobile Manufacturers Association. The local part manufacturers supply approximately 80% of all truck parts used for assembly of pick-up trucks, approximately 55% of passenger cars used locally. The locally produced assembly parts include engines, suspension control and spring, axles, hubs, propellers shafts, brakes, clutches, steering systems, body parts, electronic parts, air conditioning, tires, wheels, internal and external trim components and glass. Besides local sub-contractors, Japanese assemblers, U.S. and European companies have entered the fray by bringing their own suppliers into the Thai auto industry as well. This has expanded the automotive industry in Thailand tremendously while leaving other new manufacturing countries like Vietnam or Indonesia far behind due to the industry expertise.

Promising Trends:

The political unrest had affected tourism in Thailand, which is Southeast Asia’s second-largest economy. The car production and exports scenario however remained unaffected. The key players of the car OEMs such as Toyota, Isuzu, Honda, Mazda, Mitsubishi, Ford, GM, BMW and so on are affirming to increase the investment in Thailand. Recent announcements are such as;

– Ford Motors insists an operating plant in Thailand by shifting its pickup truck production to the country. Thailand is expected to become Ford’s central base for Asia’s production.

– GM has invested in setting up new ancillary units and augmenting the production capacity of its plant in Rayong to serve its Chevrolet which is in great demand in the domestic market and outside.

– Nissan said that their production output is set to double to 200,000 units in 2010. Nissan’s Thai plant makes five models of automobiles including cars and pickup trucks.

– Honda has increased its production capacity in Thailand to cater to the export demands of its international market.

– Indian Auto giant Tata Motors invested 1.3 billion baht to produce the Xenon pickup truck which has been developed and built in Thailand.

– Toyota, Honda and Ford have established research and development centers in Thailand. The reasons for Thailand’s growth in the automotive industry are many. The country has a large, skilled automotive workforce besides having associated industries for automotive parts and components. Alongside, the Thai government by the Board of Investment-BOI has continued promoting the automotive industry investment by offering tax incentives, lower import duties, one-stop visa and work permit advantages. Also multinational investors are not required to have a local partner which is an advantageous proposition compared to most other Southeast Asian countries. This has enabled BMW to fully-own an assembly and manufacturing in Amata City in Rayong. As such, Thailand is fast becoming a power to contend with, considering the automotive industry and automotive manufacturing trends are indeed promising.