Continuing form the last issue, if we order M10 Gauge Block made of Grade 1 Stainless Steel for micrometer calibration, how do we know if we get a good quality gauge block or not?

Continuing form the last issue, if we order M10 Gauge Block made of Grade 1 Stainless Steel for micrometer calibration, how do we know if we get a good quality gauge block or not?

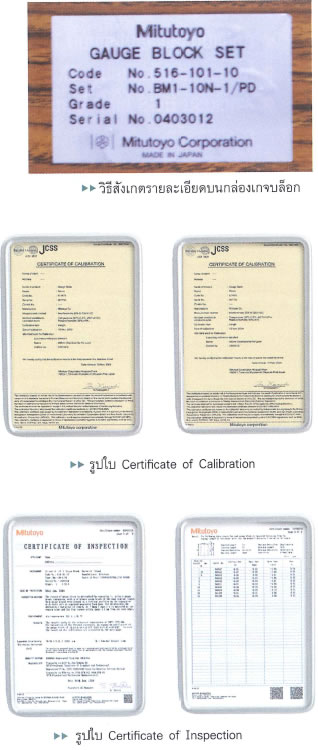

First,the box that contains the gauge block will provide the following information such as Model/ Code number, Serial Number and Grade. If all of these are included, then it is sufficient to trust the manufacturer.

Second, we should look at the manufacturer’s Certificate of Calibration. If this is provided, then there is no need for further testing although it does not specify our company’s name. However, there may be some problems if it is only a Certificate of Inspection because the inspector may reject it. Therefore, we need to send it to be tested at an ISO/IEC 17025 certified calibration laboratory before using the item (this would incur twice as much expense).

Thirdly, each gauge block should be inspected manually for any line, break, crack or dent on the surface. Also, there should not be any rust. “It is sufficient to clean the gauge block with alcohol and coat with Vaseline or oil for protection. For this purpose, it is sufficient to use 95% or ideally 100%. However, inhaling too much pure alcohol could ruin user’s sinuses and could have a serious long term effect on their health, The 75% alcohol is not suitable because there is 25% water in the content.”

Anusorn Tonmueanwai

Anusorn Tonmueanwai

Chief of Laboratory, Acting Chief – Dimensional Metrology section National Institute of Metrology, Ministry of Science and Technology, Thailand With over 20 years of professional experience in metrology and an invited lecturer at the Faculty of Engineering, King Mongkut’s University of Technology Thonburi