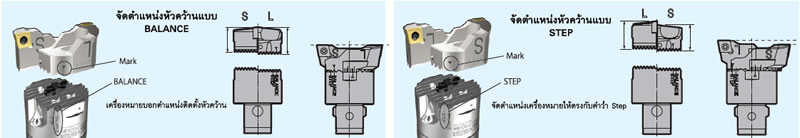

The world’s leader in precision boring systems for both roughing and finishing, has introduced the SW Boring Head for stable roughing operations. The new design displaying serrations on both ends of the tool body and the insert holder enables the SW Boring Head to execute both balance cutting and step cutting. The serrations on the extended diameter were grinded out for fine adjustment.

The world’s leader in precision boring systems for both roughing and finishing, has introduced the SW Boring Head for stable roughing operations. The new design displaying serrations on both ends of the tool body and the insert holder enables the SW Boring Head to execute both balance cutting and step cutting. The serrations on the extended diameter were grinded out for fine adjustment.

Diameter adjustment is easy and speedily done with the use of a single wrench (no need for a tool presetter) to move the cartridge to the plus and minus directions. The scale on the insert holder lets the user know the approximate diameter after boring. There is a special coating on the tool body and insert holder for complete protection against corrosion caused by chips and coolant.

In addition, the SW Boring Head was also designed for large stock removal with step boring, where the tool is set to provide a different height for the insert holders, which leads to one insert cutting in the axial direction and the other cutting in the radial direction. This achieves 2 times the chip removal of normal operations.

The SW Boring Head is available in diameters of 20 ~ 203 mm, and is suitable for roughing operations that require high rigidity,precision and ease of tool setting. This product has marked another milestone of Big Daishowa Seiki.