Mild steel or structural steel are the materials most suitable for building structures owing to them being strong, robust, flexible, tough, and can be welded together easily. Thus, in the building of highway bridges, railway bridges or bascule bridges, mild steel is very important.

Mild steel or structural steel are the materials most suitable for building structures owing to them being strong, robust, flexible, tough, and can be welded together easily. Thus, in the building of highway bridges, railway bridges or bascule bridges, mild steel is very important.

According to the principles of civil engineering of steel structures, planning, preparation, and each steel component will need to be prepared in a factory before being set up as a completed steel structure at the construction site. The good thing about of the preparation of the steel structure components in the factory is that the quality of the components can be controlled according to set standards. Having the components being precise and accurate helps to economize on costs, and what is also important is that it is safer than preparing components at the construction site.

However, before the movement of the steel structure from the factory to the construction site, there needs to be the set up of each component of the steel structure first. This will be done through them being welded or bolted together, for which the holes will need to be prepared at the factory. But, as mild steel or structural steel is often produced from rolling, this leads to inconsistencies in the flatness and thickness of the steel, which is a major obstacle for the drilling of holes, and causes the drill bit to crack and chip, which reduces the working life of the tool and may have an effect on capital costs.

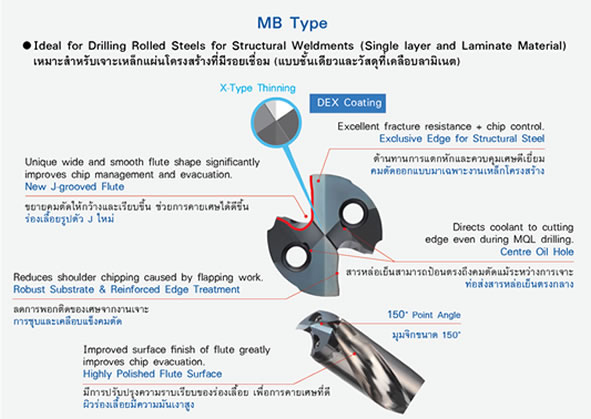

Thus, drilling of structural steel needs to use drill bits that have been specially designed for use with structural steel. Therefore, SUMITOMO Electric Hardmetal Corp. has researched and developed the SEC-Multi Drill SMD Type that has been designed with a replaceable carbide head, and is specifically suitable for the drilling of structural steel. The SEC-Multi Drill SMD Type comes with the MB Type drill bit head, which undergone development of the holder so as to grip it durability against friction from metal fragments; significantly increasing drill efficiency. At the same time, it has been designed with special cutting blades to resist chipping, as well as grooves designed according to the principles of the J-Flute that help control steel chips.

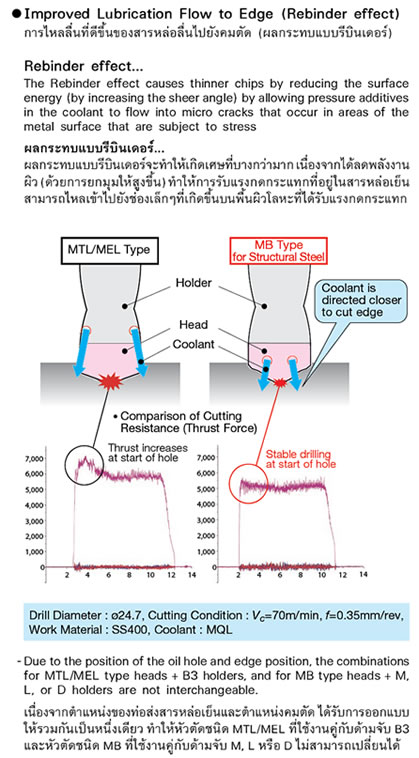

Other than this, the cutting blades of this special drill bit have been coated the latest “DEX Coat” technology with Super Multi-layer TiAlCr/TiSi. This makes this new drill bit have excellent wear resistance. As well as that, it has been designed with coolant holes for the coolant to flow closer to the drilling hole in order to reduce forces when the drill bit starts work, which is particularly important when drilling structural steel.

All of the above characteristics of the SEC-Multi Drill SMD Type and the new MB Type drill head from SUMITOMO make this drill bit the most suitable for modern drilling of structural steel. This is because, other than being strong, robust, accurate and precise, it has a working life that is longer than other drill bits by 1.7.–.3.0 times, which helps significantly reduce capital costs and working time.