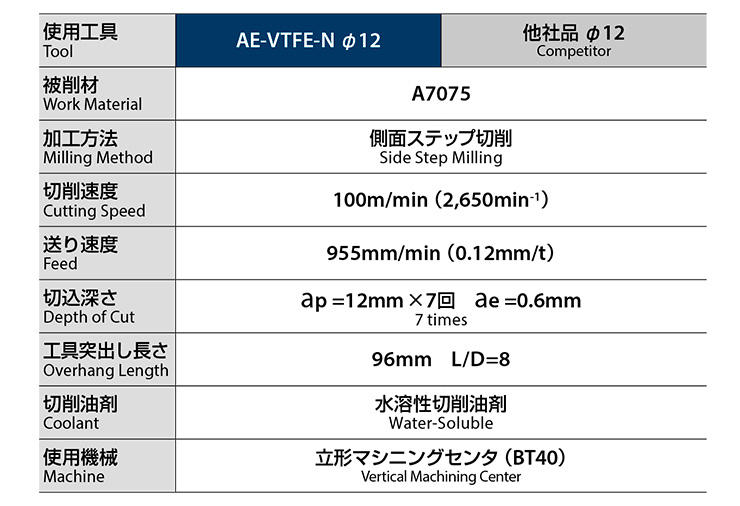

The high performance DLC coated carbide end mill for non-ferrous materials is suitable for a wide variety of applications with high efficiency and quality. Its DLC-IGUSS coating further improves tool life with excellent welding resistance and lubricity, which is effective in the machining of non-ferrous materials such as aluminum alloys.

Features

1. DLC-IGUSS coating

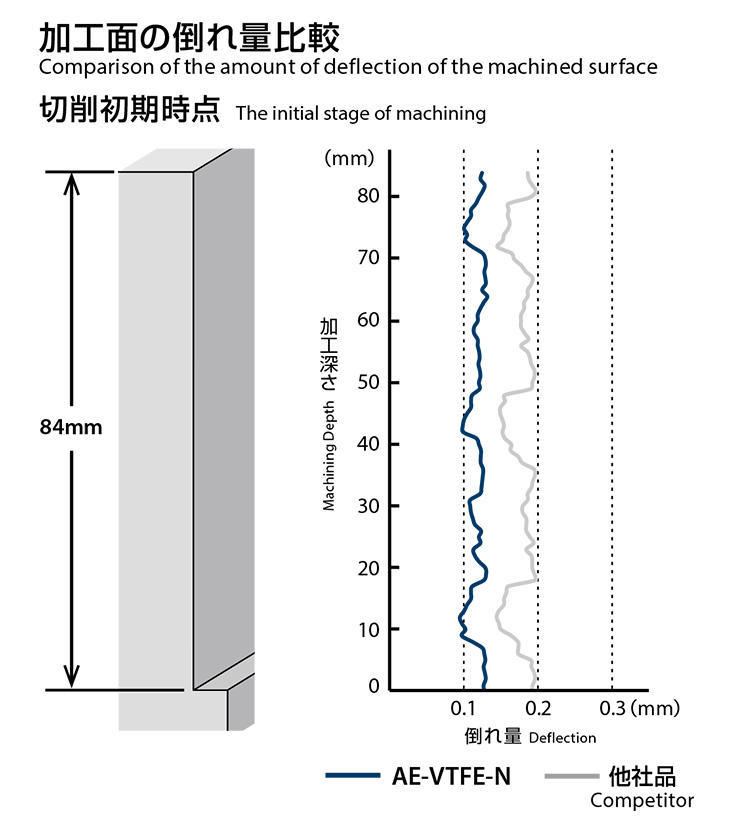

2. Flat cutting edge specification achieves higher precision machined surface quality

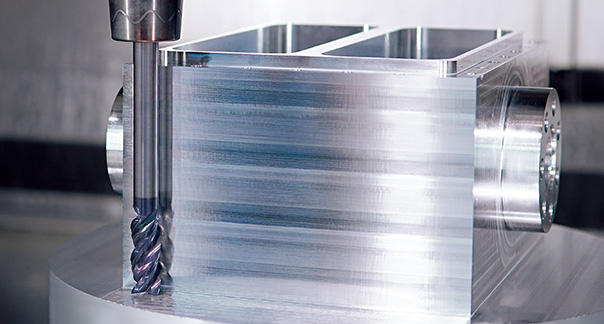

3. The long length reduced shank type supports deep side milling and pocket milling of non-ferrous metal parts

4. High efficiency and high accuracy deep side milling can be achieved by large step milling up to 2 x D with the 2.5 x D cutting length configuration

5. With an R shape on the shank side edge, streak generation can be suppressed by side step milling

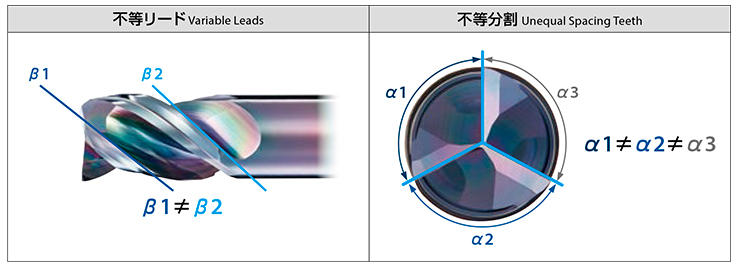

6. High anti-vibration effect by the combination of variable lead and unequal spacing teeth