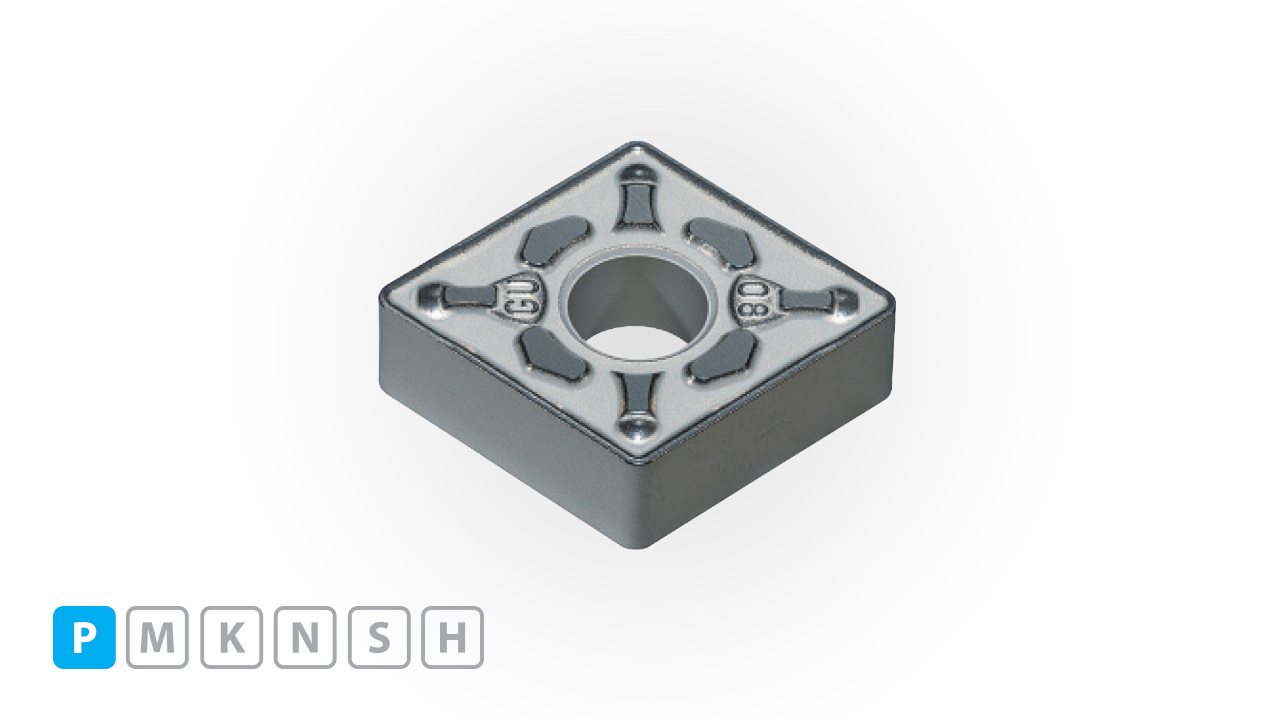

COATED CARBIDE GRADES

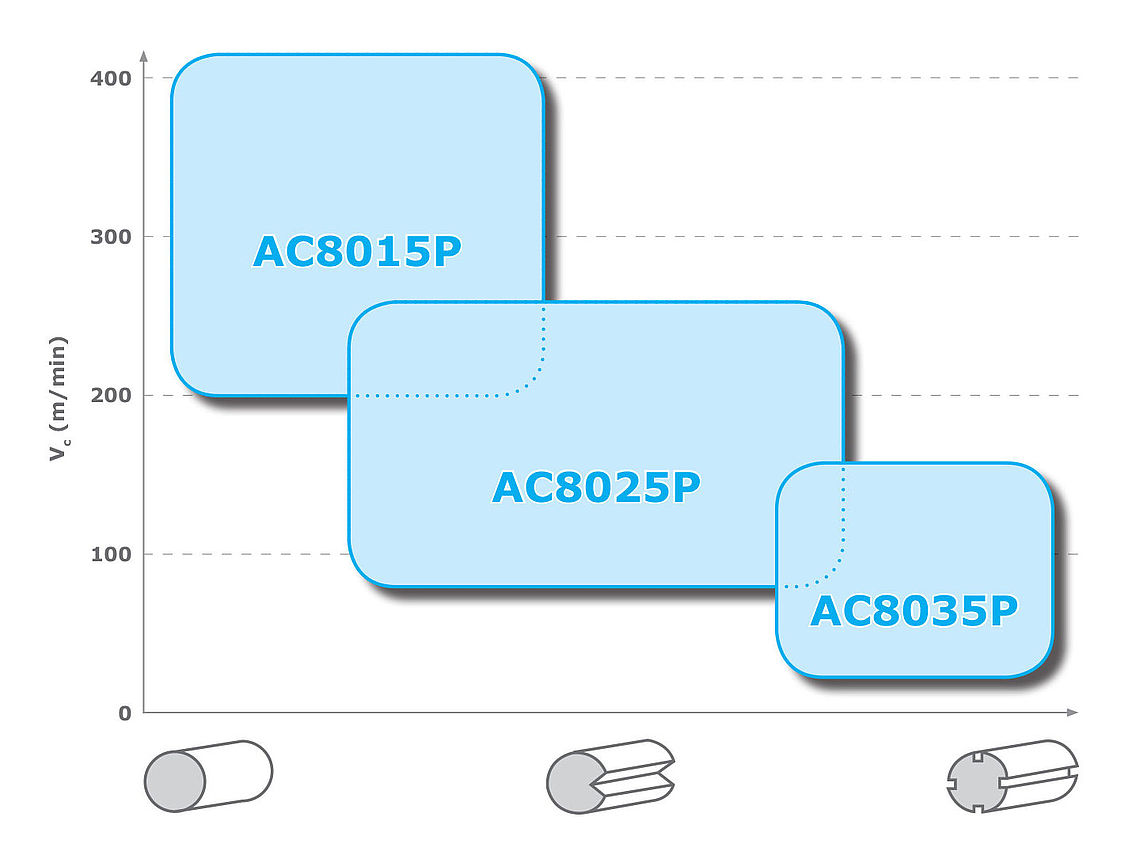

Besides our general purpose grade AC8025P, the AC8000P Series have been expanded with two new grades named AC8015P for high speed cutting and AC8035P for heavy interrupted cutting.

- Absotech Platinum Technology

- Excellent stability

- Reliable processes

- Excellent wear resistance

GRADE SELECTION

AC8015P – HIGH SPEED CUTTING

- 1st recommendation with NGU chipbreaker

- NGE chipbreaker for higher efficiency

- Improved crater wear resistance

- Increased tool life

AC8025P – GENERAL PURPOSE

- 1st recommendation with NGU chipbreaker

- Improved tool surface smoothness

- Significantly reduced adhesion

- Excellent reliability

AC8035P – HEAVY INTERRUPTED CUTTING

- 1st recommendation with NGU chipbreaker

- NUX chipbreaker for higher stability

- Excellent toughness

- Drastically reduced tensile residual stress in coating