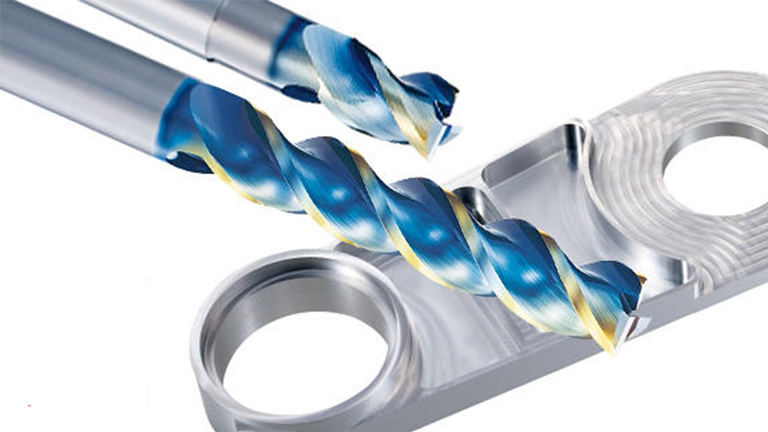

Square and radius types in a wide range of sizes from diameter 3 mm to large diameter 25 mm have been newly added to the lineup.

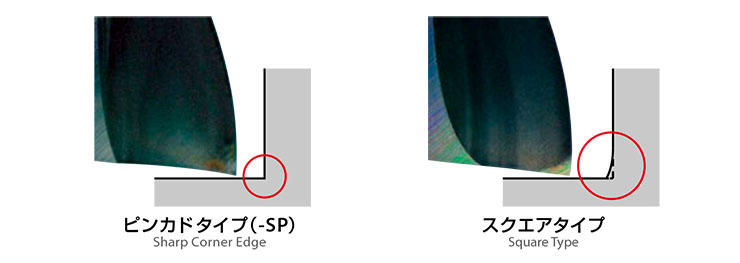

This versatile end mill series can be used in a wide range of fields, from part processing to applications in the aerospace industry. In addition, a sharp corner edge type for milling straight corners has been added to the lineup to meet a wide variety of application needs.

Features

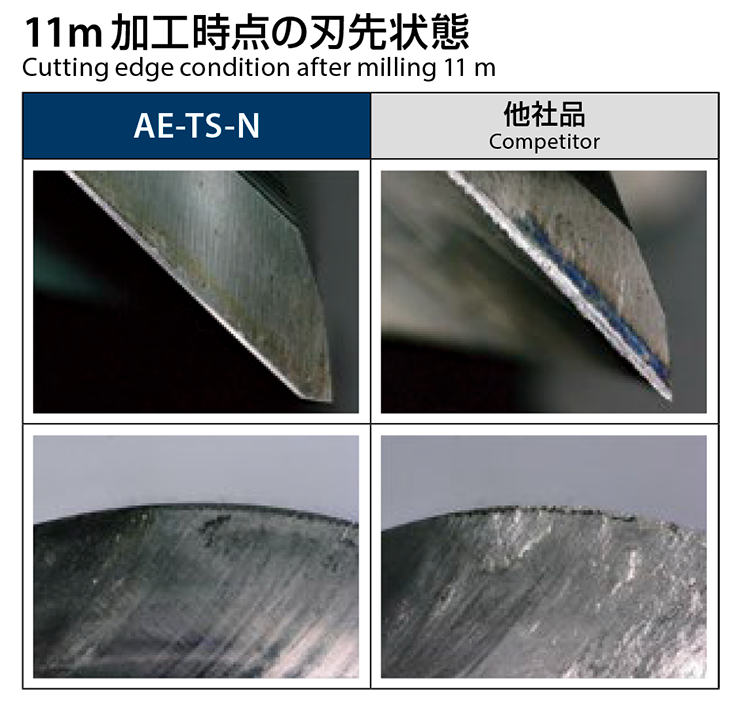

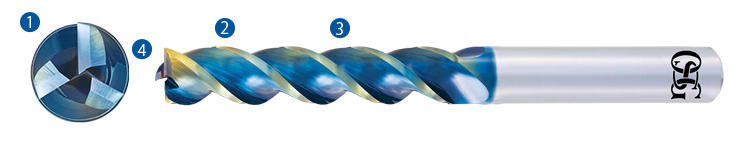

1. DLC-SUPER HARD coating

2. Cutting edge specification that achieves both rigidity and sharpness

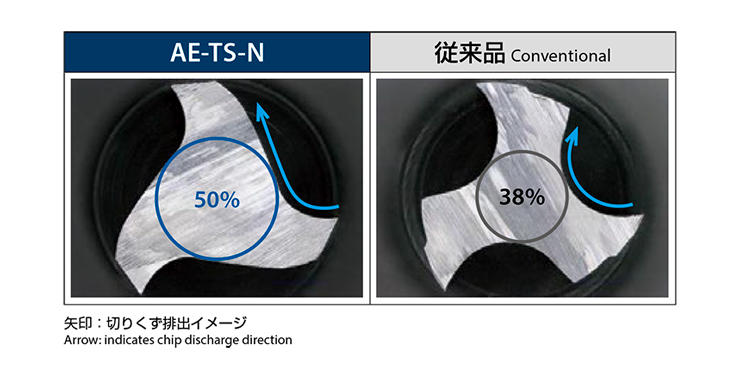

3. New flute form enables excellent chip evacuation

4. Center cutting edge specification to enable plunging

- Large core design with high rigidity to prevent chattering

- Sharp corner edge type: for milling straight corners with no uncut residue