Replaceable drill bits with replaceable heads It uses a unique sawtooth-like radius edge design. For high precision and rigidity

- Replaceable drill bit heads provide new cutting edges. Higher productivity And the price is not high and the tools are easy to handle. Allowing sharpening to 1.5 mm to 3.0 mm further reduces tooling costs.

|

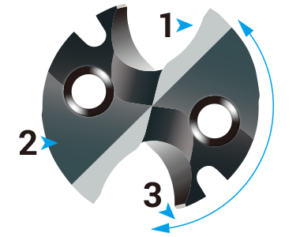

Optimized design for drilling general steel, high efficiency. 1. Sharp, strong outer cutting edge 2. Adjusting the large cutting edge |

|

Optimized design for highly ductile materials used for large casing pipes. 1. Special cutting edge adjustment designed to deal with the situation of cutting and low clamp rigidity. 2. Use a high-strength substrate that prevents unexpected breakage when working with expensive materials. 3. Large thinning angle designed to reduce driving force in very rough cuts. *Strong helix angle design provides better chip control when drilling in tough materials. |

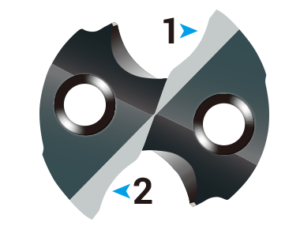

Designed to be ideal for difficult-to-cut materials such as stainless steel, mild steel, and gray cast iron. and with low strength

- Excellent cutting edge design for SUS and mild steel etc. (such as SS materials)

- The large thinning angle prevents breakage at the R-profile bulge, especially when drilling mild steel. It also reduces breakage caused by build-up when drilling stainless steel.

- Improved cutting edge breakage at the channel exit on cast iron.

|

Improved cutting edge sharpness at the outer cutting edge prevents cracking at the channel exit when drilling cast iron.

1. Sharp outer cutting edge |

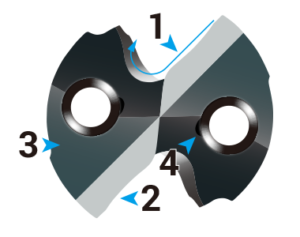

Designed to be ideal for drilling rolled steel for welded structures. (single or nested sheets)

|

1. New J-flute design. The unique wide and smooth flute shape greatly improves chip control and chip removal.2. Excellent chipping resistance and excellent chip control With a cutting edge specifically designed for drilling structural steel.3. High rigidity substrate and enhanced cutting edge adjustment Reduce breakage of the outer cutting edge caused by sudden work shifts4. Oil compartment in the middle It delivers coolant to the cutting edge even during MQL drilling. * Peck angle 150° * High quality polished flute The smooth flute surface greatly improves chip removal. |