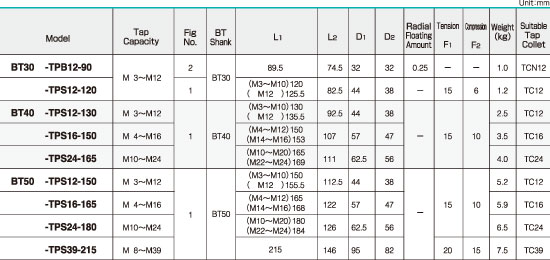

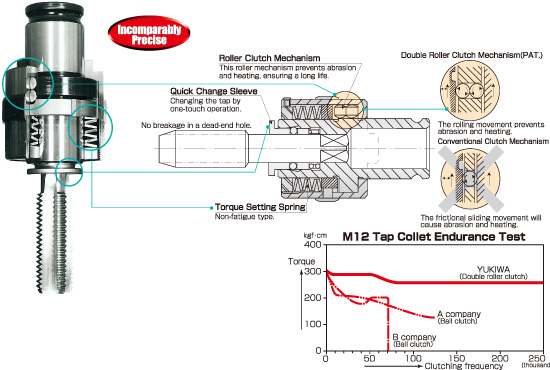

กลไกคลัตช์แบบลูกกลิ้ง

- กลไกคลัตช์แบบธรรมดาจะทำให้ลูกเหล็กสัมผัสกับคลัตช์โดยเสียดสี ซึ่งจะทำให้คลัตช์เสียดสี และทำให้จำเป็นต้องปรับแรงบิดใหม่หลังจากการคลัตช์ 10,000 หรือ 20,000 ครั้ง ในทางกลับกัน กลไกคลัตช์แบบลูกกลิ้งคู่ของ YUKIWA ไม่จำเป็นต้องปรับใหม่แม้จะคลัตช์ไปแล้ว 250,000 ครั้งก็ตาม

การจัดเรียงสปริงที่สมบูรณ์แบบด้วยคอมพิวเตอร์คำนวณ

- เนื่องจากสปริงปรับแรงบิดได้รับการออกแบบอย่างเหมาะสมโดยคอมพิวเตอร์เพื่อให้เข้ากับขนาดของต๊าป จึงทนทานต่อการใช้งานเป็นเวลานานโดยไม่เมื่อยล้า

ระบบเปลี่ยนด่วน

- การเปลี่ยนต๊าปและคอลเลทด้วยสัมผัสเดียวจะช่วยเพิ่มประสิทธิภาพในการทำงาน

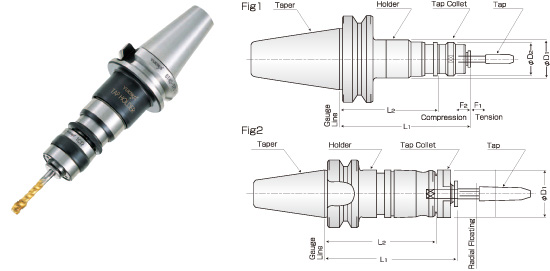

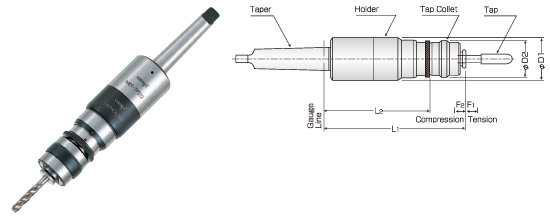

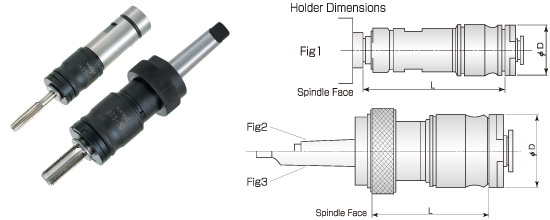

กลไกการลอยตามแนวแกนในตัว

- ข้อผิดพลาดของระยะพิทช์ระหว่างเกลียวต๊าปและการป้อนจะได้รับการชดเชยโดยกลไกการลอยตามแนวแกนในตัว (กลไกแรงดึง/แรงอัด) ซึ่งจะทำให้มั่นใจในการต๊าปที่แม่นยำ

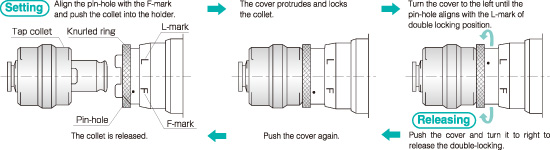

วิธีการตั้งค่าและปลดปลอกรัดก๊อก

【การตั้งค่า】

1. เมื่อดันคอลเล็ตต๊าปเข้าไปในที่ยึด ฝาครอบที่มีวงแหวนเป็นสันจะยื่นออกมาและล็อคคอลเล็ต ในเวลานี้ รูเข็มจะต้องอยู่ในแนวเดียวกับเครื่องหมาย F

2. หมุนฝาครอบที่มีวงแหวน knurl ไปทางซ้ายจนกระทั่งรูเข็มเพื่อให้ตรงกับเครื่องหมาย L นี่คือตำแหน่งล็อคสองครั้ง

【ปล่อย】

1. ดันฝาครอบด้วยวงแหวนที่มีปุ่มไปทางด้านตัวยึดประมาณ 2 มม. แล้วหมุนไปทางขวาจนกระทั่งรูเข็มอยู่ในแนวเดียวกับเครื่องหมาย F

2. ดันฝาครอบอีกครั้ง จากนั้นคอลเล็ตก๊อกน้ำจะถูกถอดออก