Base Master Series is a precision touch sensor to determine workpiece offsets and tool length.

- They can be mounted on the workpiece surface or machine table.

- An LED lamp illuminates immediately when the cutting edge touches the sensor plate and the position is detected.

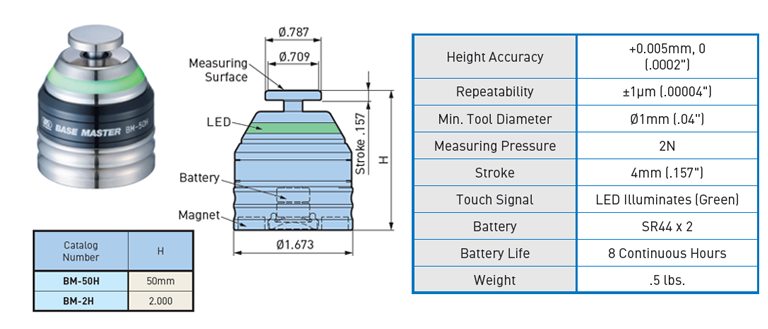

For conductive materials

BM-50H

- Quick detection of the cutting edge position. 360˚light ring for the ultimate visibility.

- Electronic detection of the cutting edge position. Repeatability ±1μm (.00004″).

- Measures 2″ or 50mm from cutting edge and workpiece top surface.

- For use with conductive cutting tools, workpieces and machine tools.

- Model without magnets is available

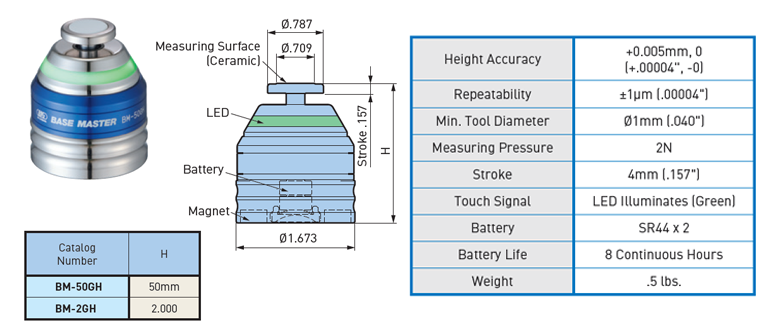

For all materials

BM-50GH

- Electronic detection of cutting edge position. Repeatability ±1μm (.00004″).

- Model without magnets is available

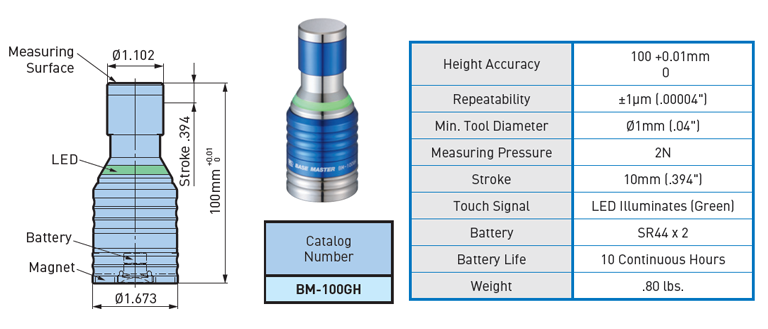

BM-100GH

- Easily Visible Measuring Surface, Even With Large Machines

- Cutting edge detection position of 100mm from machining object top surface.

- Model without magnets is available

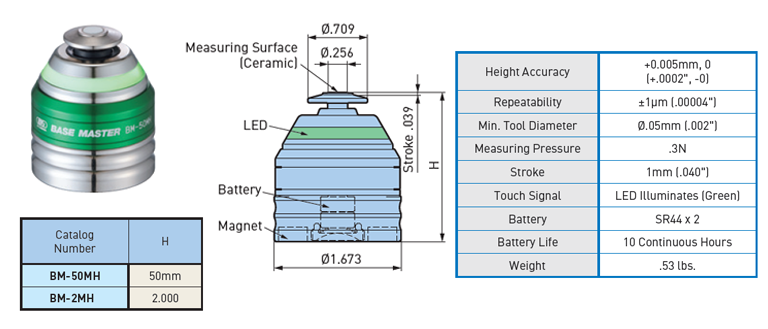

BM-50MH

- Cutting edge position detection of Ø.05mm (Ø.002″) tool.

- Low-contact pressure cushion mechanism realizes measurement of ultra-small tools.

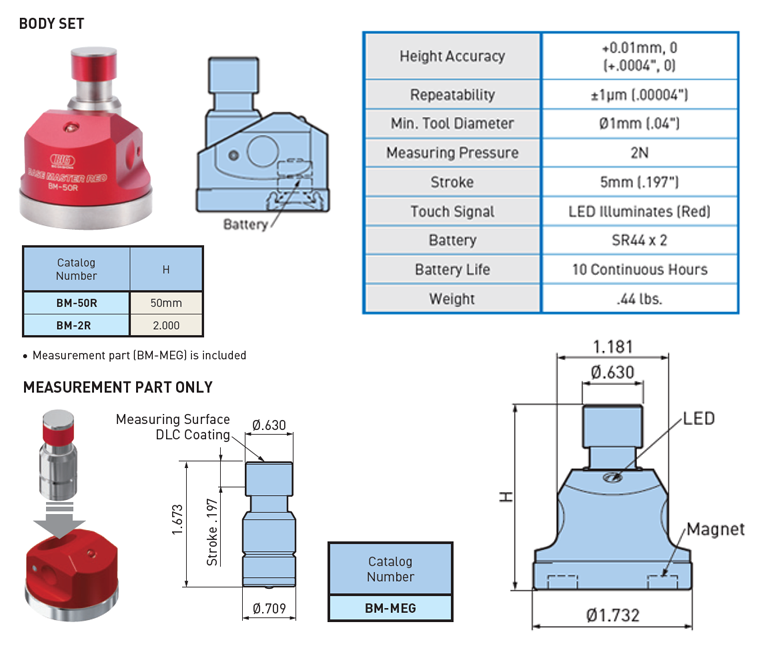

BM-50R

- Measuring unit can be easily replaced.

- Independent body and measurement part.

- DLC coated Sensor Plate. Safe stroke amount of 5mm.