Mold makersand other machined-part manufacturers are familiar with both solid tools and indexable tools. Solid tools satisfy users with their rigidity, thus resulting in a greater accuracy and surface finish; however, they are not friendly in terms of tool change and tool cost. Indexable tools, in contrast, enable users to experience greater machining efficiency and cost saving, but there is a compromise in terms of accuracy and surface finish.

Mold makersand other machined-part manufacturers are familiar with both solid tools and indexable tools. Solid tools satisfy users with their rigidity, thus resulting in a greater accuracy and surface finish; however, they are not friendly in terms of tool change and tool cost. Indexable tools, in contrast, enable users to experience greater machining efficiency and cost saving, but there is a compromise in terms of accuracy and surface finish.

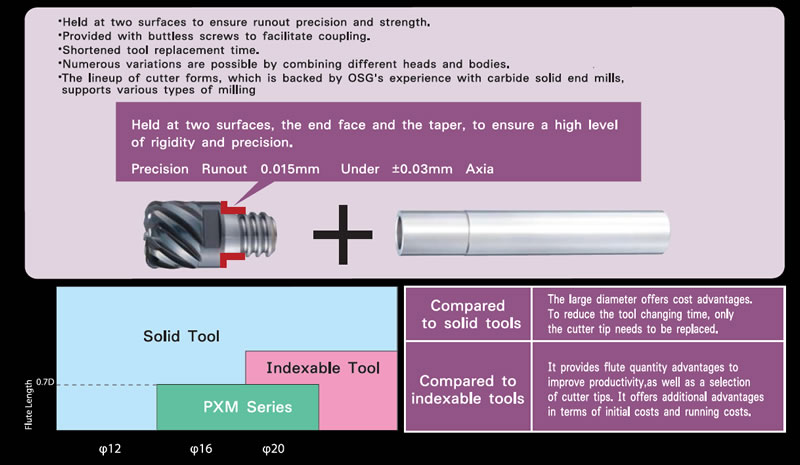

The PXM (Phoenix Exchangeable Milling) from OSG smartly combines the advantages of both types of tools while reduce their drawbacks too. The PXM from OSG fulfills the vital requirements of parts manufacturers; increase productivity by reducing the time for tool changing, lowering the tool cost (initial cost and running cost), providing a high-quality surface finish, and most importantly the exchangeable-head PXM offers a wide ranging product line that cover a variety of applications.

The exchangeable PXM from OSG features the highest rigidity and run out precision with 2-surface coupling technology, one is end face and the other is taper face. The run out level towards vertical is ±0.005 mm and toward horizontal is ±0.03. In addition, the specially designed buttress screw guarantee easy, fast and repeatable fastening and unfastening that helps reduce tool changeover time dramatically.

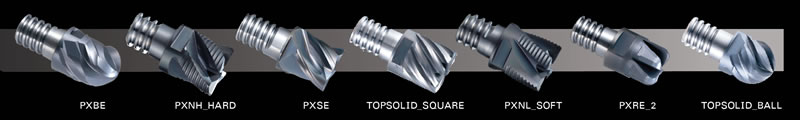

The PXM series is available with a variety of milling head forms for various applications. The PXSE features 4 flutes for general purpose work and can be used for heavy cutting from slotting to side milling. The PXSM features multiple square-type flutes for general purpose work with the advantages of multi cutters. The PXNL has four flutes with a low-helix design for roughing. The PXNH has 4 flutes with a high-helix for roughing. The PXRE is a high-feed corner radius type suitable for high-hardness materials. The PXBE is a ball type with 3 flutes that can perform highly efficient roughing. The PXBM features a multiple-flute ball nose type that is used for intermediate to finish milling.

“Customer requirements define the demand of the market, and only a tool maker that meets those requirements is the true leader. With OSG’s vast expertise and long experience in tool technology, it’s no doubt that the PXM series will bridge the gap between solid tools and indexable tools to help users improve productivity and efficiency while saving cost.”