For those who are having a big challenge from some orders that require tapping on carbon or alloy steels, today OSG has a new solution to help you achieve high stable performance over long life of tools.

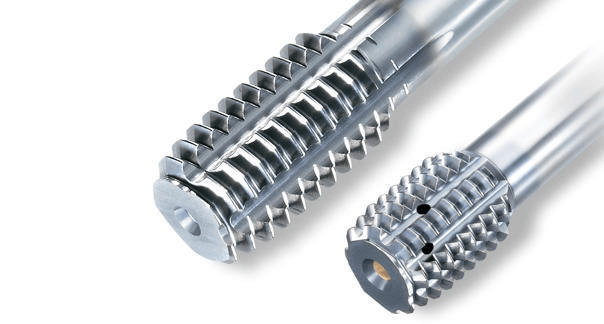

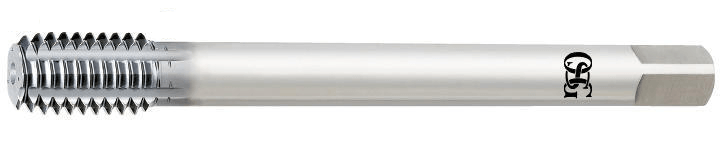

Introducing OSG New TAP X Performer Forming (S-XPF) Conventional forming tap is suitable for soft material and flexible material. (for example stainless steel) But this OSG newly invented taps can be used with carbon and alloy steels. Also, there are no problem with jamming of chip, which is typically happening in cutting taps. Moreover, this is particularly effective for machining steel forgings for automotive application. The use of special threading profile enables the tap to reduces torque and heat generation, which results in stable, long tool life even the time of using water-soluble cutting fluid. Stable tapping performance can be achieved because of the high wear resistance and toughness of the cobalt HSS substrate. Lastly, the excellent wear resistance and anti- welding properties of the V coating provide the S-XPF with stable tool life.

1. It is good for carbon and alloy steels. This prevents from jamming of chips This is particularly effective for machining steel forgings for automotive application.

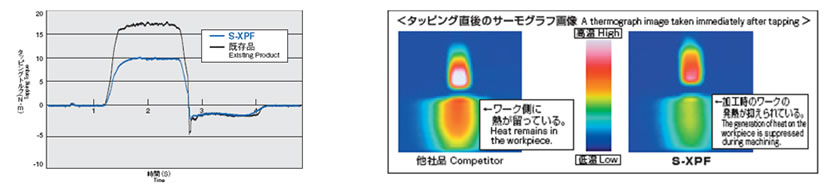

2. The special geometry of tap reduces torque and heat generation, which results in stable, long tool life even when using water-soluble cutting fluid.

3. Toughness of the cobalt HSS substrate has high wear resistance, which results in stable tapping performance

4. V coating provides the S-XPF with stable tool life because the coating has the excellent wear resistance and anti-welding properties.