In recent years, there has been an increasing trend of difficult-to-machine materials which aims better quality workpiece. Meanwhile, the machining processes are demanded better precision and higher speed. The trend has came for better production, but it also addresses a tremendous challenge to the industry. So does threading process, when cutting the difficult materials and speeds are not well reconciled, then the tap may be broken in the hole while cutting, causing stoppage while machining. The further challenge is that how to take out the broken tap as fast as possible to resume threading process in order to prevent long non-machining time.

In recent years, there has been an increasing trend of difficult-to-machine materials which aims better quality workpiece. Meanwhile, the machining processes are demanded better precision and higher speed. The trend has came for better production, but it also addresses a tremendous challenge to the industry. So does threading process, when cutting the difficult materials and speeds are not well reconciled, then the tap may be broken in the hole while cutting, causing stoppage while machining. The further challenge is that how to take out the broken tap as fast as possible to resume threading process in order to prevent long non-machining time.

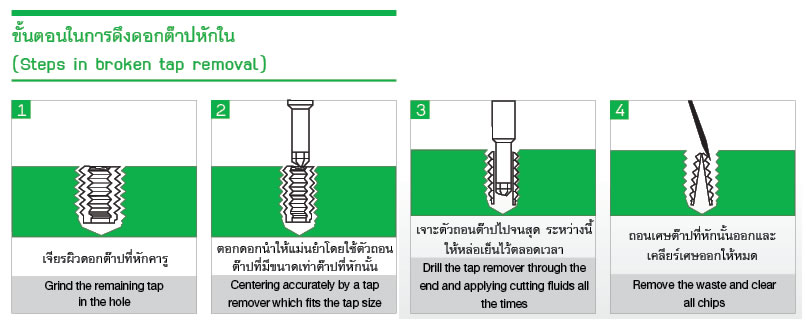

EIKO- an expert of tap removal tool- has a smart solution to remove the broken tap easily and completely. EIKO Tap Remover (TR) Plus is the ideal choice for broken tap removal with originally designed unique shape of flutes to remove the broken tap by drilling at the center of the broken tap. (Refer to workpiece)

Features of Tap Remover

• Drill the broken tap with hardness of HRC63 to 66.

• Not to damage thread because flute diameter of tap remover is smaller than that of drilled hole.

• Superior in anti-abrasion characteristic due to heat resisting coating.

• Operation is done very easily in a short time.

• Applicable for almost all HSS tap.

• Even the tap with slant broken section can be removed due to originally designed unique shape of flute.

• High rigidity because diameter of shank is bigger than that of flute.