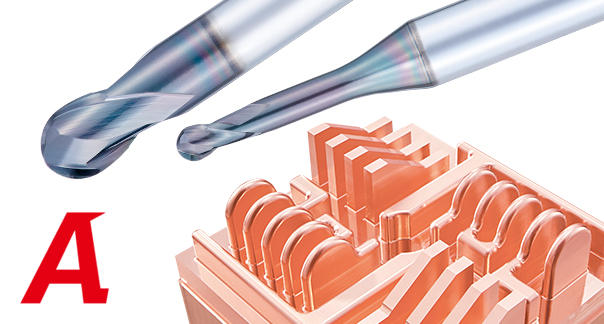

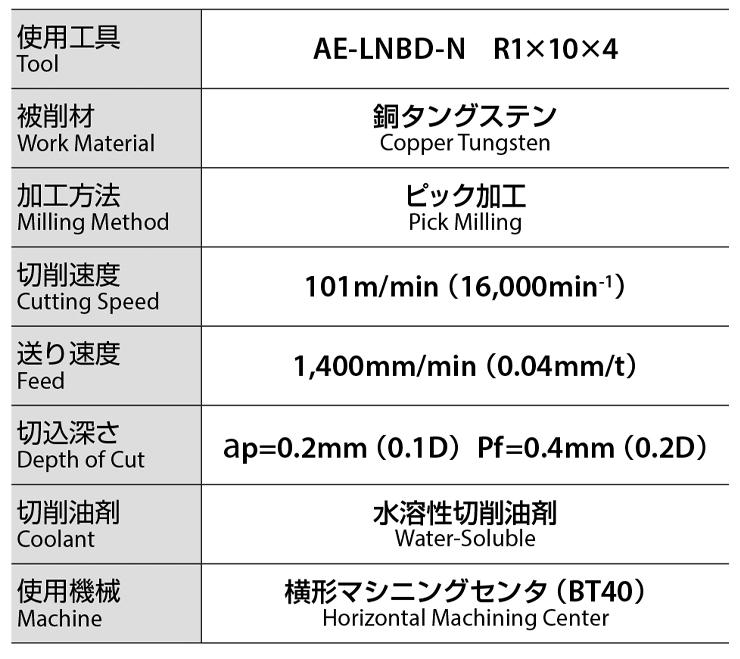

DLC Coated Carbide End Mill for Copper Electrodes

- Milling beautiful copper electrodes without burrs!

- Excellent machined surface accuracy.

- 2-flute high-precision finishing long neck ball type.

Features

Ball specifications that enable high quality milling

- DLC-IGUSS coating

The DLC-IGUSS coating, which is extremely effective against non-ferrous metals such as copper alloys that require welding resistance and lubricity, is used to enable stable milling accuracy for a long period of time. - Optimal cutting edge shape for milling copper alloy. Good edge without burrs.

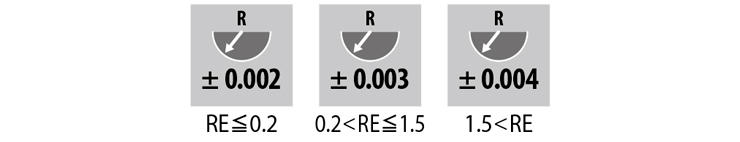

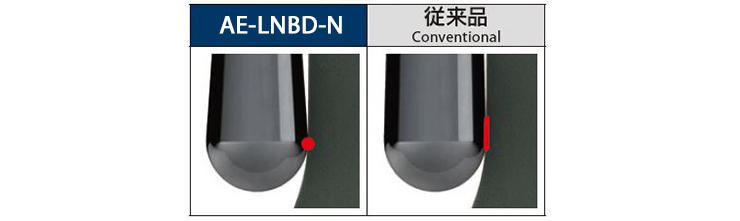

- Superior ball R precision

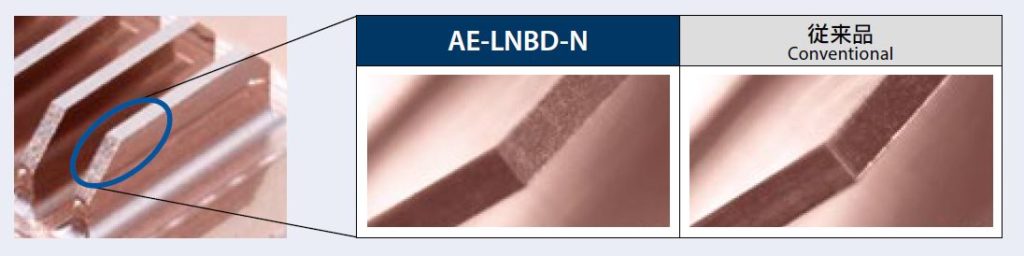

- High quality primary relief surface

Teardrop-shaped outer periphery

Strong back taper geometry enables milling by point, which prevents chattering and chipping, resulting in improvement of surface accuracy.

Superior shank accuracy

Supports h4 tolerance (0/-0.004)

Unique DLC coating that revamps copper electrode machining

- Due to its smooth surface and extremely low coefficient of friction, DLC coating is extremely effective against non-ferrous metals such as copper alloys, which require welding resistance and lubricity.

- Compared to conventional DLC coating, DLC-IGUSS is a thick film type that suppresses wear on the cutting edge and achieves both high tool durability and good machining accuracy.

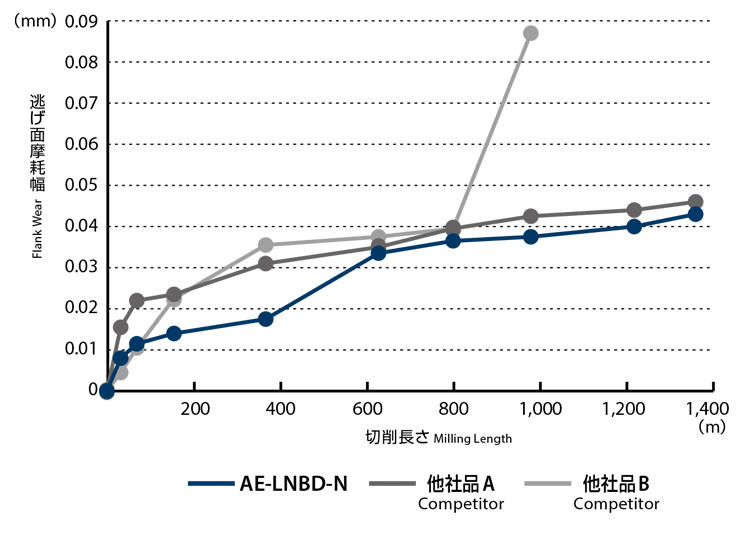

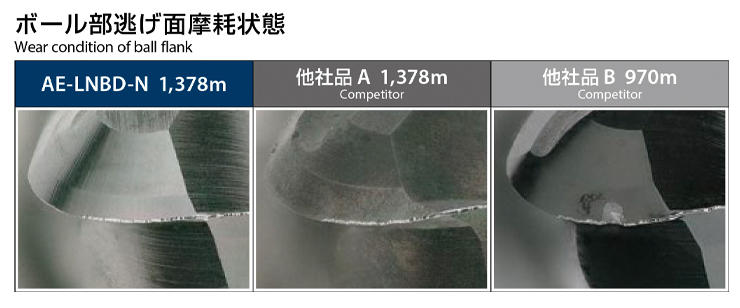

- DLC-IGUSS is effective in suppressing wear against tough-pitch copper (C1100), and stable machining accuracy can be obtained for a long period of time.

- DLC-IGUSS coating enables consistent tool wear.