The machining system that enables the next-generation double-ended surface grinding that overturns common sense

As automobiles and home appliances have become more energy-efficient and lighter and smaller, requirements for a higher quality of machined surfaces of mechanism elements used in them have become severer.

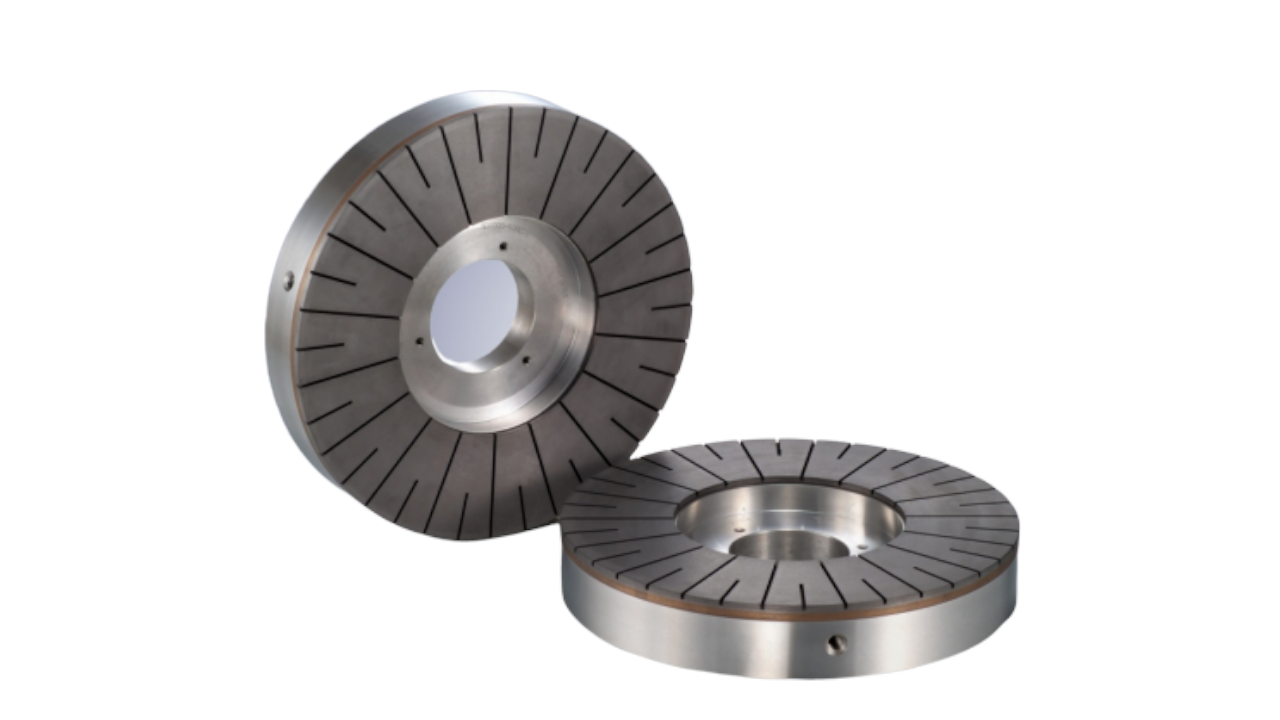

For grinding surfaces of these mechanism elements, resin bond wheels have been used in many cases, but we have developed the MB SPARK that enables further improvement of machined surfaces of these mechanism elements.

The MB SPARK when used in combination with electro-discharge truing offers significant improvement of truing intervals than resin bond wheels, overturning the common sense of double-ended surface grinding.

Characteristics

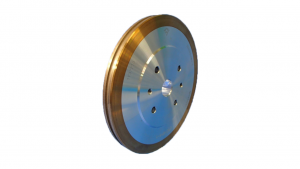

- High accuracy

- high efficiency and long life can be achieved in double-ended surface grinding. Since the general grinding wheel is not used for truing

- the amount of sludge is reduced and therefore the amount of wastes can be reduced. Compared with the resin bond wheel

- the amount of wear is smaller and the capability to retain the flatness of the grain layer is greater. The highly rigid special metal bond improves the grain holding power. Since the

- good abrasive surface generated by electro-discharge truing is maintained

- the wheel stays sharp for a long time.