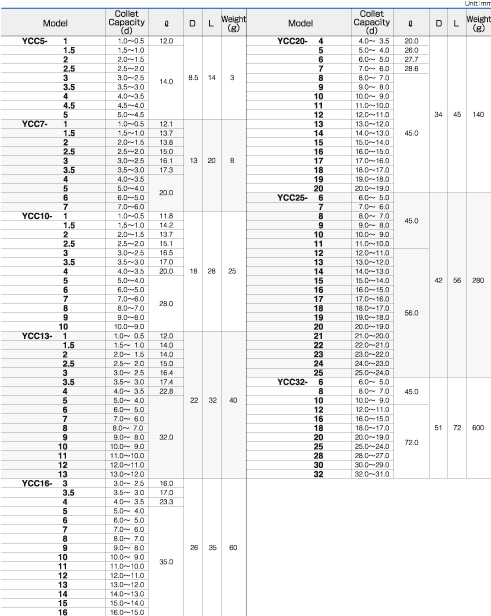

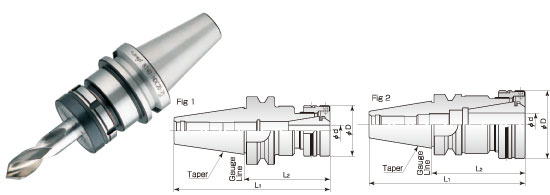

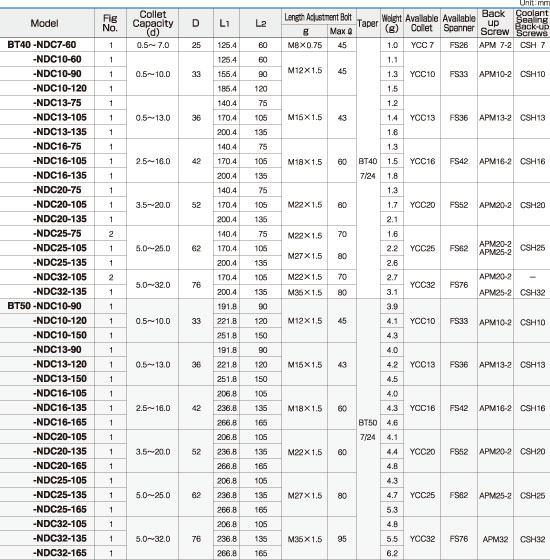

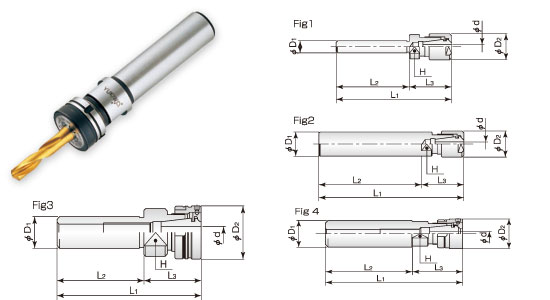

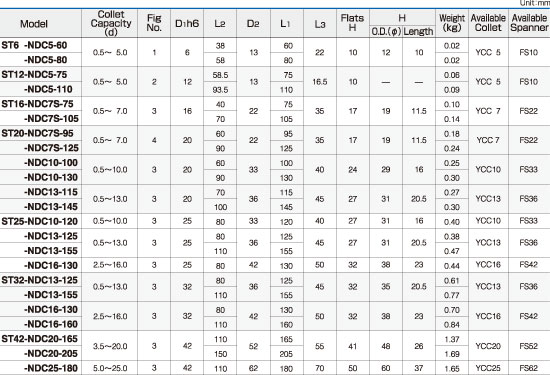

1mm chucking range per one collet

- YCC drill mill collet be squeezed up to 1mm to the nominal collet capacity.

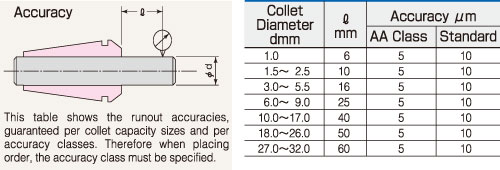

Super Precision

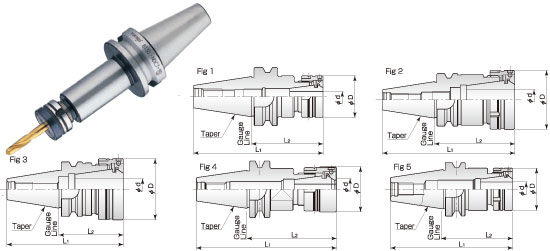

- Wall-thickness of the hole where the collet to be inserted is made thicker for higher rigidity and for less deviation of the runout accuracy.

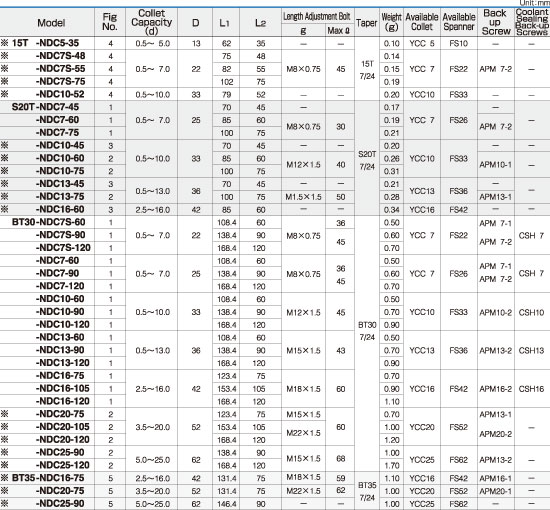

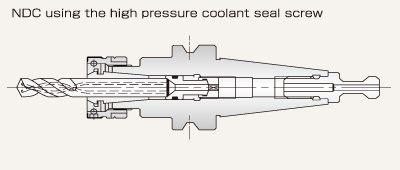

Coolant of higher pressure can be used

- By setting the coolant seal screw,the high pressure spindle -through coolant of 7.0MPa(70kg/cm²)can be used.

v

High balancing

- Grinding of the external surface of the holder secures a high balancing.

Being flat on top between locknut surface and collet surface

- The shorter projection of the tool improves accessibility to the work.

With the coolant seal screw,the chuck can use the high pressure coolant(spindle-through type)

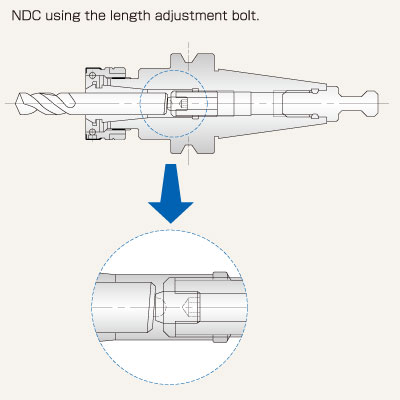

The length adjustment screw of APM type secures the high runout accuracy by preventing tool inclination

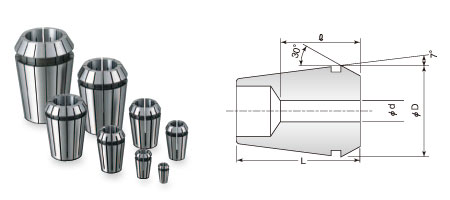

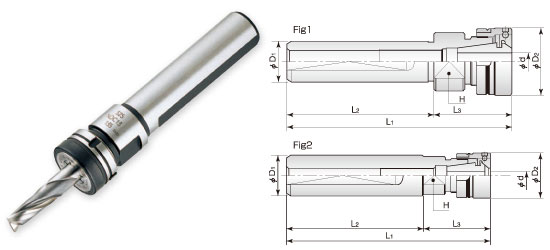

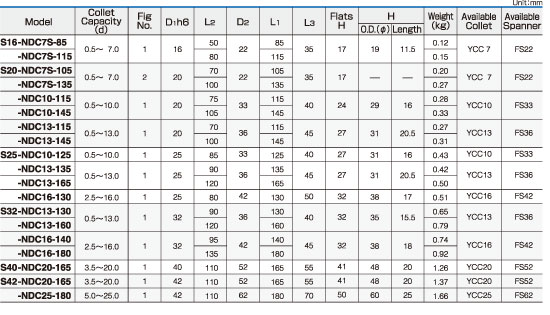

High-accuracy Drill-Mill Collets

- The Drill Mill Collets are the result of more than 40 years of our experience and achievement as a maker specializing in collet chucks,being made by the superior heat-treatment and precision-machining technologies utilizing the selected materials.They are highly accurate and durable.

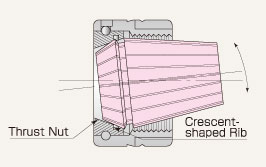

Simple and Ensured On-Off of Collets

- A crescent-shaped rib is fitted on the inside periphery of the lock-nut.Place the collet into the lock-nut and tilt the collet slightly so that the crescent-shaped rib fits securely into collets circumferential notch.When the lock-nut and collet have been assembled and screwed to the chuck body,insert the tool into collet and tighten lock-nut with spanner wrench.

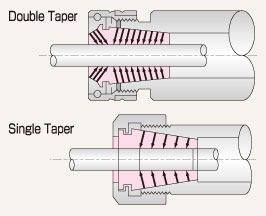

Strong Gripping Torque

- Tanks to double taper on our drill mill collet and using our lock nut with steel balls,the tool gripping length can be longer than that of the single taper collet,thus making the gripping torque much stronger.

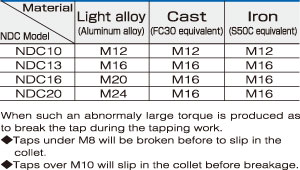

Can be used also as Tap Holder

- Our drill mill chucks are often used also as tap holder for the high-speed and precision tapping work on the machining center having a synchronizing mechanism of the spindle rotation and feeding.Our drill mill chucks can hold the following taps and perform the tapping work.