CNC Vision Measuring System Equipped with a Touch Trigger Probe

QVTP Pro is a CNC Vision Measuring System equipped with a touch trigger probe. Non-contact measurement and contact measurement can be done solely by one unit. QVTP Pro can perform contact measurement by using the vision measuring function and the touch trigger probe. Three-dimensional workpiece measurements can be performed. Enables 3D measurement of workpieces such as press-molded products, plastic-molded products, and cut products, which until now could not be measured with image processing alone.

Non-contact and contact measurement on one machine

Non-contact and contact measurement on one machine

- QVtouch- triggerprobeunitenablesbothvisionmeasurement andtouch-triggerprobemeasurement.

3D workpiece measurement

- Enables 3D measurement of workpieces, suchaspress-molded products,plastic-molded products, and machined products,that until now could not be measured with image processing alone.

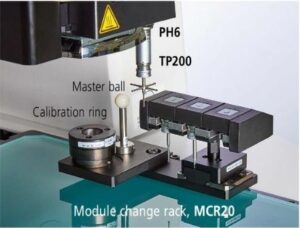

Module change rack available

-

-

-

- Using the module change rack enables switching between vision measurement and touch probe measurement during an automatic measuring sequence.

- Using the module change rack enables switching between vision measurement and touch probe measurement during an automatic measuring sequence.

-

-

Features

- All the QUICK VISION Pro models are equipped with a strobe light, and the newly developed vision measuring function “Strobe Snap” delivers measurements with both high throughput and high accuracy. Regardless of the continuity of measuring positions, measuring time can be shortened by about 35 to 45% for most measurement samples. Due to the excellent compatibility with part programs allows a part program to be created for high-speed measurement with ease.

- The image auto focus of QUICK VISION Pro can measure the height of mirror-finished surfaces through to rough surfaces, such as machined surfaces and plastic molded parts, with high accuracy and at high speed under any conditions. Image auto focus speed has been improved by about 30% compared with conventional models.

- Height change in a workpiece can be tracked in the Z-axis direction quickly by laser with the Tracking Auto Focus (TAF) function. StrobeSnap and STREAM allow it to perform effectively, resulting in a significant increase of measurement throughput.

- The Point From Focus (PFF) function enables the 3D measurement with multi cross-section images. Scanning the object by auto focusing the objective lens can capture multiple cross-section images (image contrasts) at different heights. Thus obtaining 3D shape data from such images.