Drilling is a vital metal cutting operation in part production for automotives, motorcycles, aerospaces, computers, electrical components, mold & die, medical, etc. Drills used in the drilling process is demanded to provide optimum performance which is strongly required, including high precision, minimizing drilling time, fast smoother chip evacuation, as well as long life, for instance. The drills have to be well designed by incorporating with all success factors in the right combination, they are; cutting edge geometry, drill flute, substrate and coating material.

Drilling is a vital metal cutting operation in part production for automotives, motorcycles, aerospaces, computers, electrical components, mold & die, medical, etc. Drills used in the drilling process is demanded to provide optimum performance which is strongly required, including high precision, minimizing drilling time, fast smoother chip evacuation, as well as long life, for instance. The drills have to be well designed by incorporating with all success factors in the right combination, they are; cutting edge geometry, drill flute, substrate and coating material.

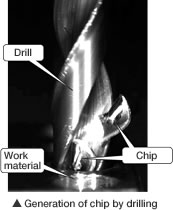

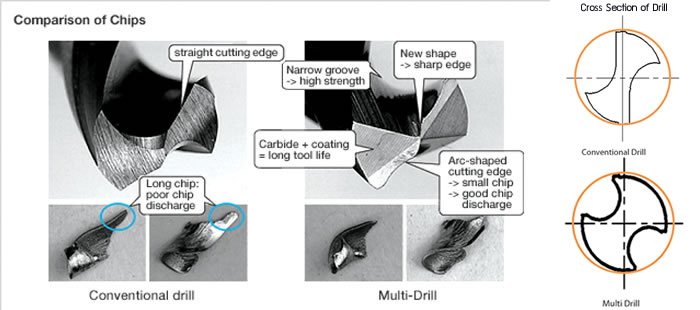

As drills have to bear extensive torque while drilling, therefore a large cross section is necessary to attain the drill’s rigidity. However, a design of large cross section results in relatively narrow space between drill teeth along the flutes creating a significant problem in chip evacuation (Fig 1). Moreover, inappropriate chip sizes and shapes cause a drilling failure due to the chip clogging in such a narrow space between tooth. In other words, chips must be small enough to move up the drill’s flutes and out of the way smoothly. For such reasons, modern drills are designed in ARC shaped cutting edge.

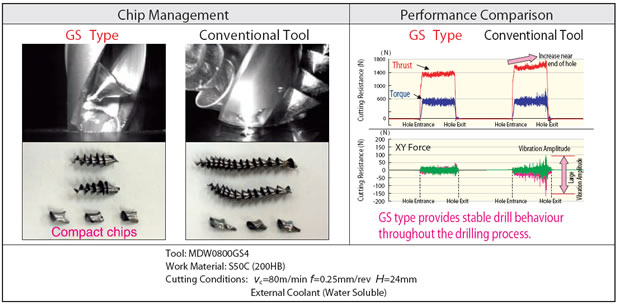

Fig 2 demonstrates the new innovative designed drill which provides small chips, being easy to remove while drilling. This exceptional design is beyond the conventional norm in drill designs.  Not only the new concept of cutting edge, but a new flute shapes is also developed. The conventional design, teeth spacing along the flute is quite wide with a belief that it can remove chips faster. On the contrary, new teeth spacing nowadays comes in a curve shape in order to force chips to be curled then broken into small fragments before flowing up through the flutes easily. The arc shaped cutting edge and curve flutes’ teeth enhance a drilling operation better, smoother chip flow, lower force and minimized error, eventually the workpiece is highly accurate.

Not only the new concept of cutting edge, but a new flute shapes is also developed. The conventional design, teeth spacing along the flute is quite wide with a belief that it can remove chips faster. On the contrary, new teeth spacing nowadays comes in a curve shape in order to force chips to be curled then broken into small fragments before flowing up through the flutes easily. The arc shaped cutting edge and curve flutes’ teeth enhance a drilling operation better, smoother chip flow, lower force and minimized error, eventually the workpiece is highly accurate.

Besides the two success factors, drill substrate is very important too. Good substrates and coating techniques allow high wear resistance and extend tool life. Usually, a good drill is made of cemented carbide which contains high TRS value (Transverse Rupture Strength value) which means it provides higher stiffness resisting to breakage. In addition, for increasing wear resistance, TiCN, TiN, TiAlN coating layers are adopted. This makes the drills far more durable and longer life. Most of all, coating technology is essential, and improved tremendously nowadays. With extra coating layers such as TiAlCr/ TiSi- so called Multi Layer Coating TiAlCr/ TiSi (DEX Coat) it even provides higher wear resistant. The new innovative multi-layer coating is equipped with DEX Coats, a film in nanometer range inserted between TiAlCr and TiSi layers. DEX Coat substantially improves resistance to wear and breakage in comparison with conventional coating techniques. The bottom line is that it extend over two times of tool life.

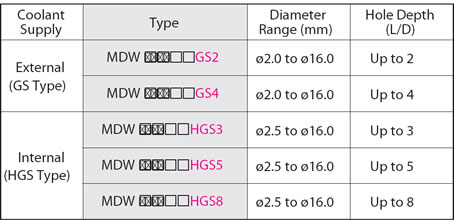

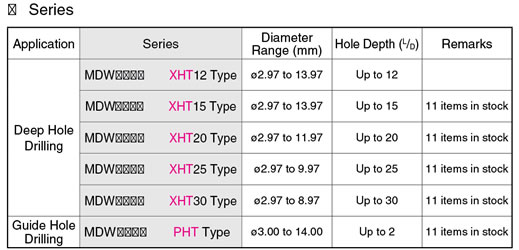

The new concept of drill design as mentioned above has become real by Sumitomo Electric Hardmetal Corp, a world’s leading cutting tool manufacturer. The innovative drills are launched in Super Multi Drills GS Type for 2X and 4X hold depth (Fig 4). The HGS Type, the tool tip coolant type and the double margin type are well suitable for high accuracy with 3X, 5X and 8X hold depth (Fig 6) as well as XHT/ PHT Type for very deep hold drilling up to 12X, 15X, 20X, 25X and 30 X (Fig 7) which be able to respond to strict demands in highly accurate applications, reducing drilling time, longer tool life and cost reduction in overall. All of these series are equipped with distinct features which are more advanced than conventional drills; the J-flute design that enables excellent chip controls and evacuation, together with DEX Coating- the only exclusive nano-based coating technology of Sumitomo Electric Hardmetal Corp , Japan.