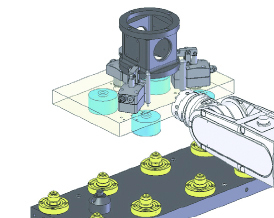

Usage

Auto jig exchange system on Machining centers

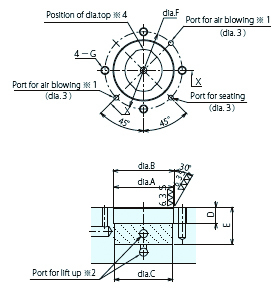

Mounting Dimensions

| № | A H7 | B | C | D | E +0.30 | F | G |

| QLH26S | 37 | 38 | 36.5 | 10 | 25.5 | 48 | M5 |

| QLH32S | 46 | 47 | 45.5 | 10 | 29.5 | 58 | M6 |

| QLH40S | 60 | 61 | 59.5 | 10 | 35 | 72 | M6 |

| QLH48S | 73 | 74 | 72.5 | 10 | 39.5 | 87 | M8 |

※Dia.pin’s top position and tapped hole are as per drawing, so machine tapped holes and port holes to follow the direction of dia.

※1.There are 2 air-blowing holes, so take use of one.

※2.Lift up port must be within area.

※3.O-ring contacted surface must be without burrs(roughness 6.3S or under)

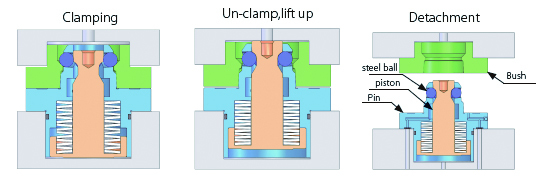

Structural drawing

Specifications

| Type | Hydraulic Type, Single Action | ||||

| Drive system | Clamping | Spring | |||

| Un-clamp | Hydraulic | ||||

| № | QLH26S*P | QLH32S*P | QLH40S*P | QLH48S*P | |

| Clamping force (kN) at 0.5MPa | 3 | 7 | 10 | 16 | |

| Lift up force(kN) at 0.5MPa | 2.7 | 5 | 7.8 | 11 | |

| Clamping stroke(mm) | 4.5 | 5 | 6 | 7 | |

| Lift-up amount (mm) | 1 | ||||

| Cylinder volume(cm3) | Clamping side | – | – | – | – |

| Un-clamp side | 3.9 | 6.8 | 14 | 24 | |

| Max. working pressure(MPa) | 5 | ||||

| Min. working pressure(MPa) | 2 | ||||

| Proof pressure(MPa) | 7 | ||||

| Recommended air blowing pressure(MPa) | 0.5 | ||||

| Fluid | Dry air | ||||

| Ambient temperature (℃) | 0~65 | ||||

| Weight(kg) | 0.5 | 0.8 | 1.4 | 2.5 | |