World-class Accuracy with Superior Maneuverability

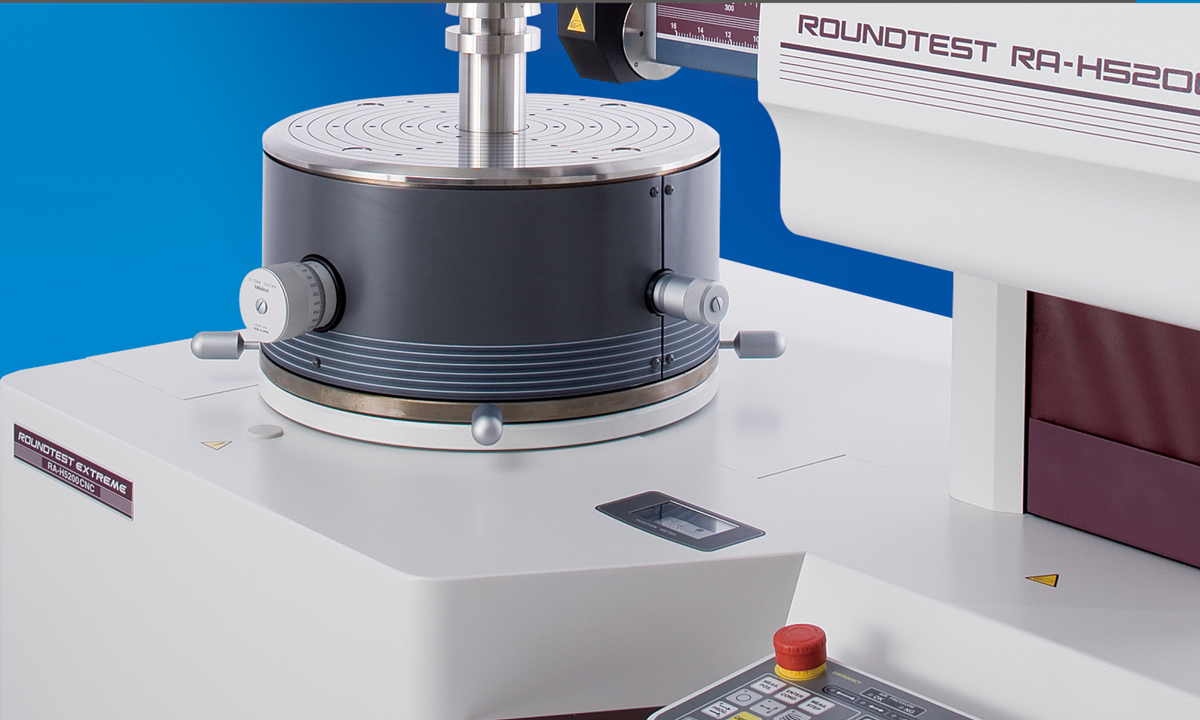

High-accuracy, automatic centering/leveling turntable

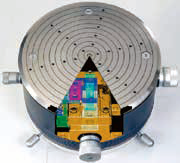

A highly accurate, highly rigid turntable has been achieved through exceptional manufacturing accuracy of the critical components, in addition to a high-accuracy airbearing that provides superior rigidity. The resulting rotational accuracy, the heart of the roundness/cylindricity measuring system, is world-class at (0.02+3.5H/10000)μm.

A highly accurate, highly rigid turntable has been achieved through exceptional manufacturing accuracy of the critical components, in addition to a high-accuracy airbearing that provides superior rigidity. The resulting rotational accuracy, the heart of the roundness/cylindricity measuring system, is world-class at (0.02+3.5H/10000)μm.

High-rigidity base

For a measurement system to be able to achieve high accuracy, the base, which forms the foundation of the system, must be completely rigid. Therefore, we utilized FEM structural analysis simulation to thoroughly analyze the base and its application. The result is the development of a high-rigidity base.

For a measurement system to be able to achieve high accuracy, the base, which forms the foundation of the system, must be completely rigid. Therefore, we utilized FEM structural analysis simulation to thoroughly analyze the base and its application. The result is the development of a high-rigidity base.

High-accuracy Z-axis column

Attaining the ultimate level of improvement in the manufacturing accuracy of the column guide surface, which is critical for achieving perfect straightness, and adopting Mitutoyo’s proprietary system and mechanisms have led to the achievement of the ultra-high column straightness of 0.05μm/100mm (in narrow range).

Attaining the ultimate level of improvement in the manufacturing accuracy of the column guide surface, which is critical for achieving perfect straightness, and adopting Mitutoyo’s proprietary system and mechanisms have led to the achievement of the ultra-high column straightness of 0.05μm/100mm (in narrow range).

High-accuracy positioning sensors

Mitutoyo’s linear encoders have been incorporated into the positioning sensors in the X- and Z-axes drive units to directly sense the displacement the drive units, thereby achieving the highly accurate positioning essential for repeat measurements.

High-performance vibration isolator as a standard feature

The measurement accuracy of a roundness/cylindricity measuring system is greatly affected by external disturbances such as vibration. Therefore, the RA-H5200 Series is supplied as standard with a high-performance vibration isolator that possesses excellent vibration attenuation.

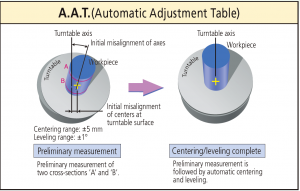

High-speed automatic centering/leveling

The system is supplied as standard with the Automatic Adjustment Table (A.A.T.) positioning and leveling function, freeing the operator from the task of centering and leveling the workpiece. High precision glass encoders are used to reduce positioning errors and achieve high-speed automatic centering/leveling, which contributes greatly to reducing the total measurement time from workpiece setting to workpiece measurement.