The New Standard in Optical Form Measurement

An exciting new addition to the Mitutoyo form measurement line

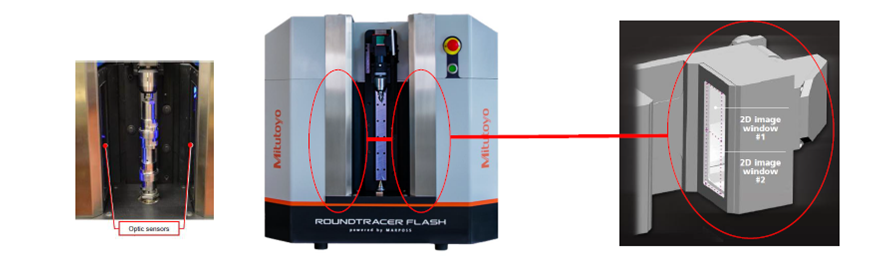

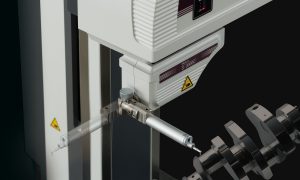

Roundtracer Flash is an optical measuring unit based on side-by-side 2D image architecture. This means that images that are acquired by different sensors are perfectly combined together in order to generate one single resultant image of the part with zero discontinuities and no gaps at the stitching edges. As a result, Roundtracer Flash is capable of measuring parts up to 300 mm in length without any vertical movement of the sensors or the part itself.

The Perfect Combination of Precision and “Flash” Cycle Time

The 2D image architecture sets a new benchmark in the measuring industry, providing significant advantages.

- High Speed – Unrivaled measuring speed, thanks to the no Z-axis movements. Full 2D optic.

- Image Consistency – Complex profiles and part geometries are acquired inside the same image frame.

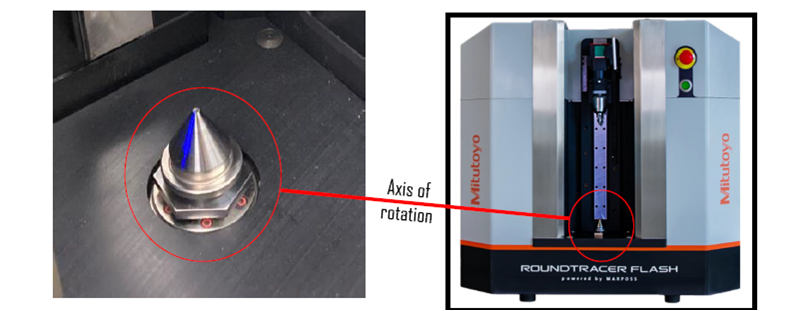

- Axial Run-out – The 2D image frame allows for the entire surface to be captured dynamically, at each angle, during the part rotation.

- Thru-holes Measurement – Only a few milliseconds are needed between the image acquisition and the measurement execution.

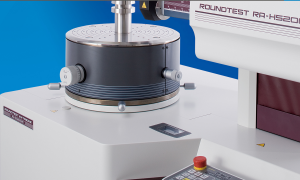

Fastener Quality Control

Screws, pins, or rivets can be easily and quickly measured with the Roundtracer Flash.

The standard measurement toolkit includes threads analysis: maximum and minimum diameter, pitch diameter, pitch value, thread angle, thread linearity, total thread length

- 2D Image Architecture

State-of-the-art area image sensors can perform many micrometric-precision checks on parts with unprecedented speed.

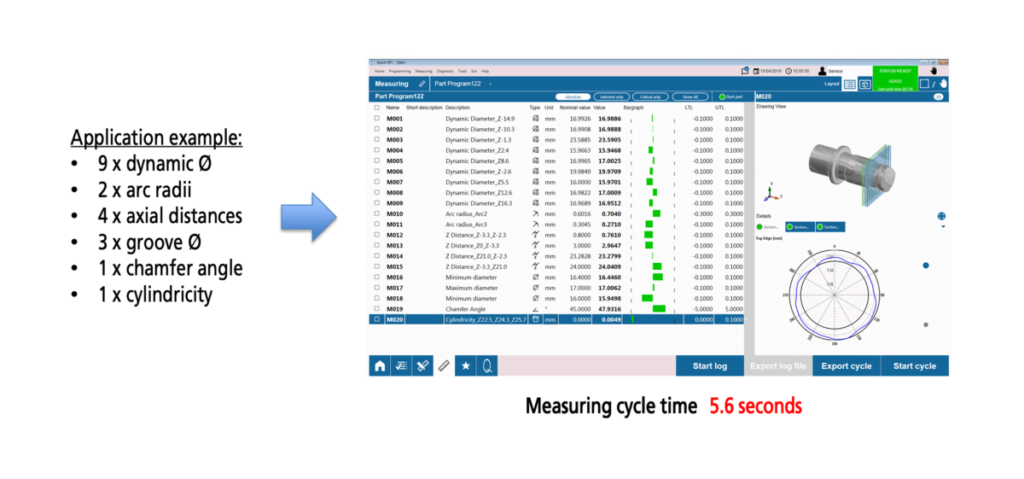

- Unrivaled Measuring Speed

With the absence of Z-axis motion the optical acquisition of the complete part – which consumes time on other systems – is performed almost instantaneously on the Roundtracer Flash. Therefore its cycle time is impressively fast. For example, it executes 100 static measurements in just 2 seconds irrespective of how the measurement sections are distributed along the shaft length!

- Static & Dynamic Mode

Dimensional, position, and form analysis can be performed in static or dynamic mode for maximum flexibility.

- Impressively Fast Measuring Cycles

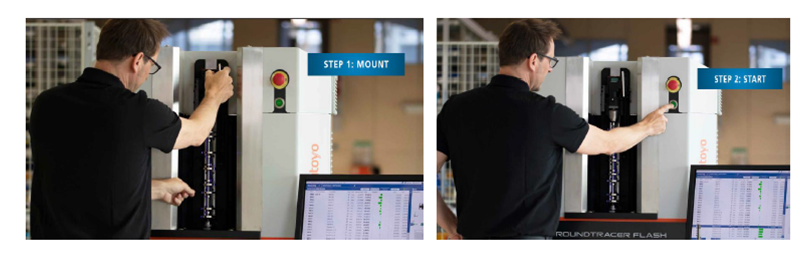

No lost of tiome between clamping of the workpiece and start of the measuring cycles.

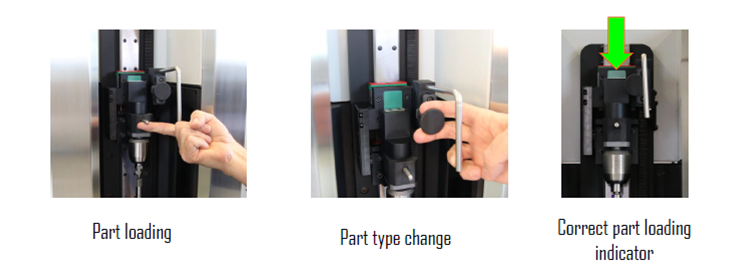

- Easy Part Loading

Open loading area with no obstructions and an ergonomic tailstock system for easy part clamping. Simply load the workpiece and start the measuring cycle.

- One-Click Measuring

All measurement cycles can be easily started by one-click activation on the Roundtracer Flash or by an icon on the touchscreen.

It is easy to use. Eliminate training costs with an intuitive user interface. Features like the easy interpretation of the measurement results, part detail images, and graphical setups. Anyone can use and also configure new measurements on the Roundtracer Flash.

- Graphical User Interface

A state-of-the-art graphical user interface with a touchscreen monitor provides excellent ease of use. Standard monitor arm provides more flexibility and freedom.

- Superior Usability

Intuitive user interface provides easy interpretation of measurement results, part detail images, smart search function and more for simple operation.

- Durability

Fixed position sensors mean there is no mechanical stress from vertical movement of the sensors or the part itself. This provides stable performance over millions of cycles with minimal maintenance requirements.

- Integrated USB Hubs

7 ports are available for connections to printers, code readers, and other external devices.