Every component produced becomes an impressive masterpiece

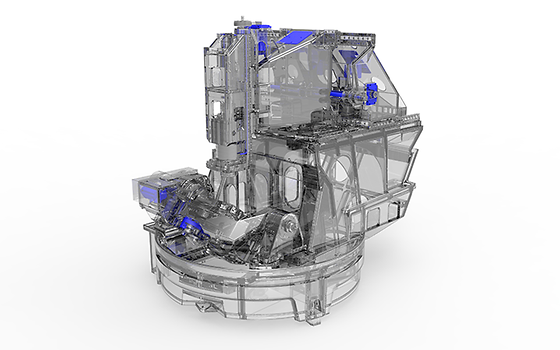

1. monoBLOCK – Maximum stability from one casting

2. 5-axis simultaneous machining

3. Highly dynamic high-speed milling with spindle speeds up to 20,000 rpm

4. Large door opening of 1,310 and unique access to the working area, most compact machine with a footprint of just 8 m²

5. Stiff construction with high static masses and balanced moving parts

Ergonomic

- Large door opening of 1,310 and unique access to the working area, most compact machine with a footprint of just 8 m²

- Unrestricted crane loading of up to 600 kg

- Quick and easy to set up thanks to its three-point support

Precise

- Comprehensive cooling measures, high-performance coolant unit and multi-sensor compensation as standard

- Stiff construction with high static masses and balanced moving parts

Stiff monoBLOCK concept

- monoBLOCK – Maximum stability from one casting

- One-piece column with large, stable slideways, 45 mm roller guideways in all axes

- Maximum stability thanks to large ball screws in all axes ø 40 / 50 / 40

- FEM optimization of all components

- Clamping of the swiveling rotary table