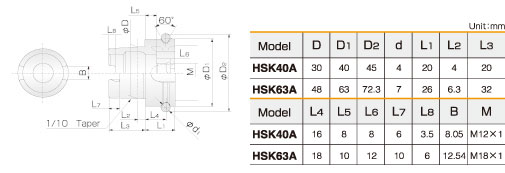

HSK Hybrid G1 Chuck

Guarantee of 3μm of integrated runout accuracy

- For standard model with the collet chuck, 3μm of integrated runout accuracy is guaranteed.

Easy operation of collet holder with higher precision than that of shrink-fit holder

- HSK Super G1 chuck adopts collet holder system, and has the same or better runout accuracy as that of the shrink-fit holders, not requiring any other special equipment such as heating device, much curtailing the tool changing time.

Usable up to 50,000min-1

- Simple and straight outside appearance, having no space of the locknut, controls to minimize the aerodynamic noise and cutting fluid dispersion. Small-sized locknut enables minimizing the floating affection to the balancing.

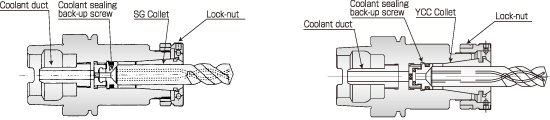

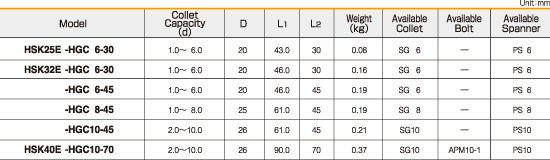

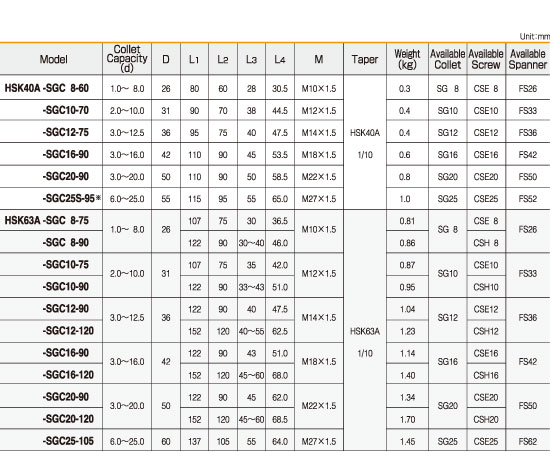

HSK Super G1 Chuck

Guarantee of 5μm of integrated runout accuracy

- As the integrated runout with the collet, the standard model guarantees 5μm of accuracy.

Strong Gripping Force

- The double taper-collet system ensures stronger grip torque than that of a single taper collet.

Super balancing, most suitable for high speed cutting

- Grinding of the external surface of the holder secures a high balancing.

Usable for operation with high-pressure coolant.

- With a coolant seal screw, the holder can be used for operation with a high pressure spindle-through coolant up to 7.0 MPa (70kg/cm3).

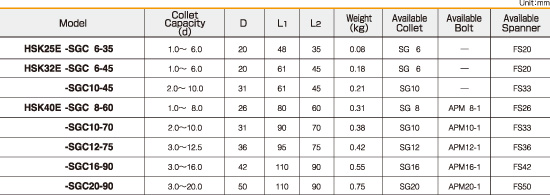

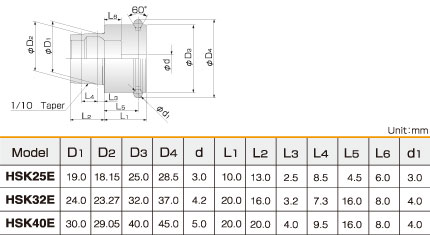

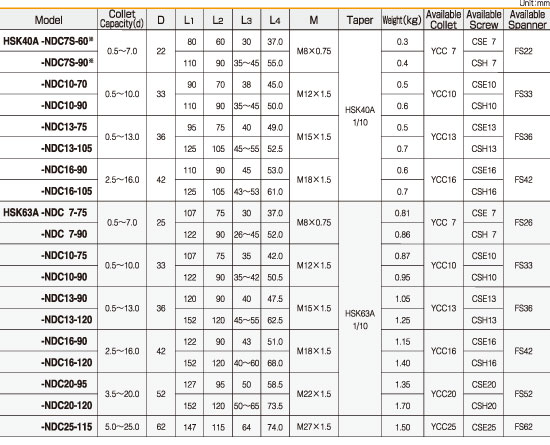

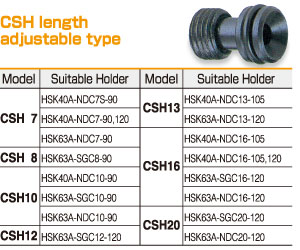

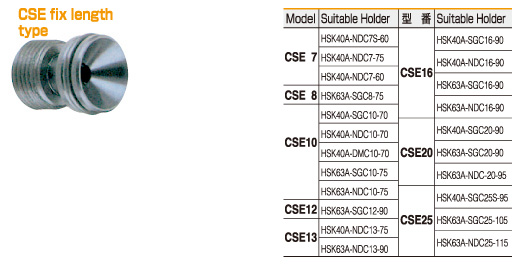

HSK New Drill Mill Chuck

Squeezing of 1mm per one collet.

- YCC drill mill collet can squeeze up to 1mm, but depending on the capacity.

High rigidity and high accuracy

- Distinguished in rigidity at the thickened collet-inserting section of the holder and minimized uneven accuracy.

Super balancing

- Grinding of the external surface of the holder secures a high balancing.

Available for high-pressure coolant

- Set a coolant seal screw and it will be available for high- pressure spindle coolant up to 7.0MPa.

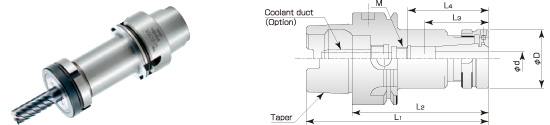

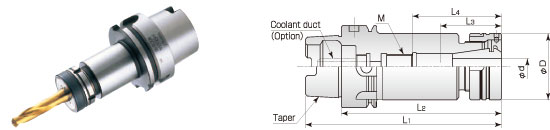

Drawing of holder using high pressure coolant