Features

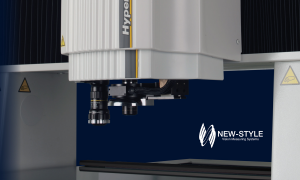

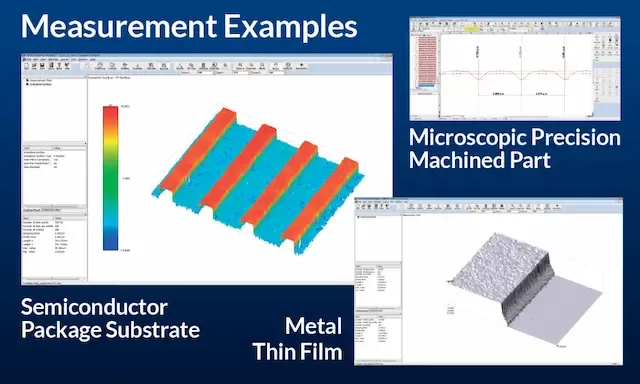

- WLI optical system can capture 3D data to perform 3D surface texture analysis and 3D roughness analysis. You can also perform dimension measurement and cross-section measurement at a specific height using the 3D data.

- The Point From Focus (PFF) function enables the 3D measurement with multi cross-section images. Scanning the object by auto focusing the objective lens can capture multiple cross-section images (image contrasts) at different heights. Thus obtaining 3D shape data from such images.

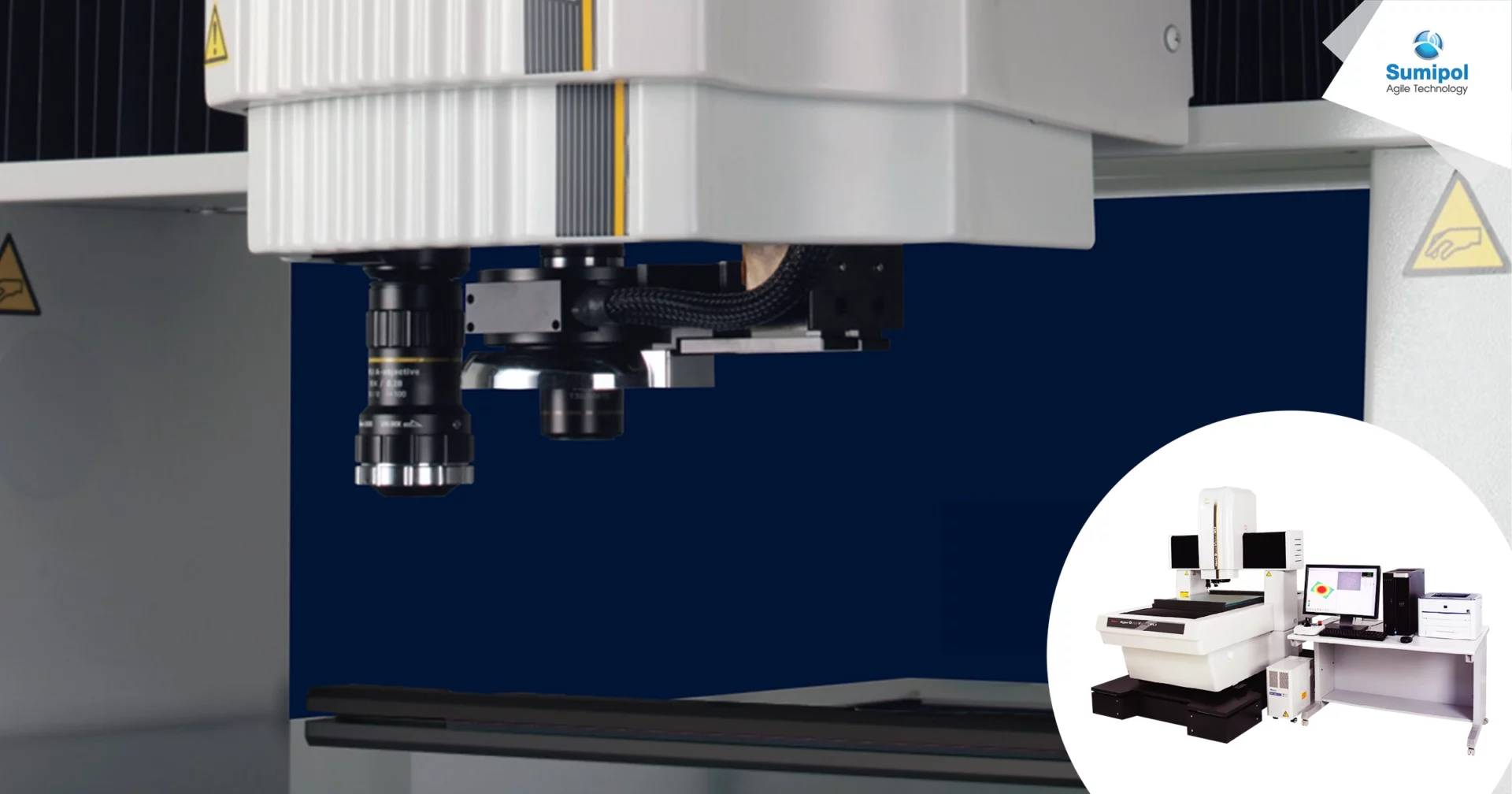

Hyper Quick Vision White Light Interferometer

High accuracy for non-contact dimensional measurement

Using white light interferometer, the Quick Vision Series can perform highly accurate 3D measurements in microscopic areas for surface analysis, small-diameter hole depth, and line and space measurements on circuit boards.

HIGH PRECISION & RESOLUTION

NON-CONTACT 2D/3D MEASUREMENT

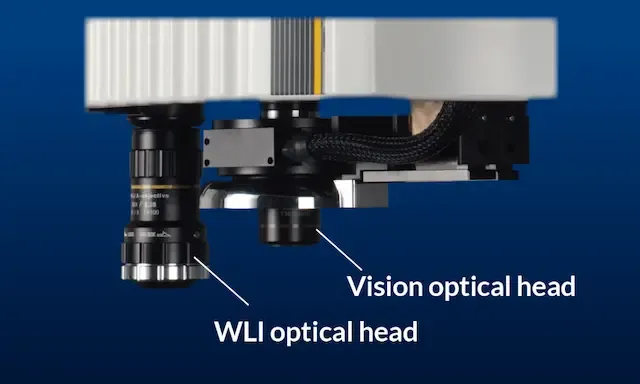

White light interferometer (WLI optical head) applied to vision measuring systems enables a wide range of powerful measurements, from 2D measurement of coordinates and dimensions, surface analysis in microscopic areas, depth measurement of small-diameter holes, and to high-precision 3D measurement of wiring dimensions on a printed circuit board.

HIGH CAPABILITY OF HANDLING

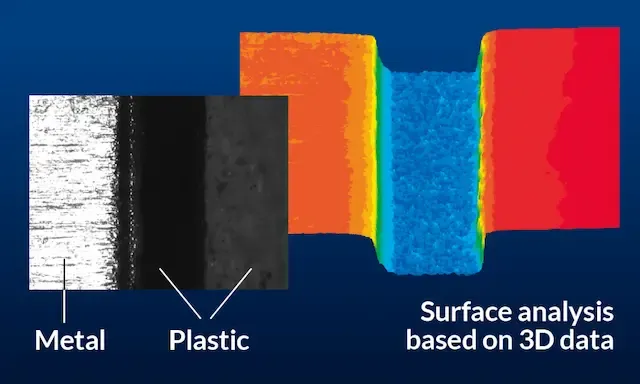

A WIDE VARIETY OF MEASUREMENT SURFACES

WLI method can handle a wide variety of measurement surfaces including diffusing surfaces and mirrored surfaces. Using Mitutoyo’s proprietary algorithm, WLI can also handle surfaces with large brightness differences, e.g., where plastic and metal coexist in mixed states.

POWERFUL SUPPORTING SOFTWARE

QV3DPAK

Synthesizes 3D shape data from interference fringes to display shapes or outputs point cloud data to external sources. 3D data can be transferred to the shape/evaluation analysis software (optional) to implement shape measurement and surface analysis.