Inspection and Calibration

- Able to check and calibrate various instruments such as Dial Indicators, Digimatic Indicators, Dial Test Indicators, Bore Gauges, Linear Gage

- Able to select the calibration standard of the instrument according to ISO, JIS, DIN, ANSI/ASME, BS, etc.

- Able to select the measurement points as needed and also set the acceptance criteria and measurement parameters of interest.

Full / Semi – Automatic Inspection System

The highlight of the i-Checker machine is the automatic measurement system technology. The measurement system is divided into 2 systems:

1. Semi-automatic measuring system is used for measuring instruments that are analog scale systems.

2. Automatic measurement system is used for digital measuring instruments.

It comes with real-time reporting, allowing users to immediately observe the error values in each measurement range, including alerts when the measurement results exceed the set acceptance criteria.

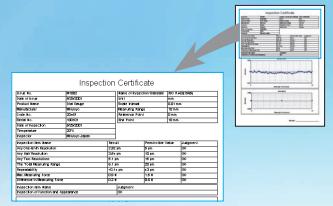

Create and printout a simplified inspection certificate

Users can design the report format by selecting to display details of the instrument, measurement results, measurement error values, and other parameter values as required, along with displaying the measurement results in graph form. In addition, the measurement results can be saved on the computer in Microsoft Excel format, making it easy and convenient to report results in the quality system.