INTRODUCING OMRON’S NEXT GENERATION I4L SCARA ROBOT SERIES

The i4L is a compact SCARA robot which offers strong performance at the lowest cost of ownership. Simple integration with compact design, easy wall or table mounting and unique Ethernet or EtherCAT connectivity in the base. Maximize uptime by means of interactive maintenance alarms and an RGB dome light.

- Easy to connect and install with a compact design that can be mounted on a wall or table.

- Unique Ethernet or EtherCAT connectivity in the robot base.

- Maximize uptime with maintenance alerts and RGB dome lights.

NOTE : ETHERCAT CONNECTIVITY AND INTERACTIVE MAINTENANCE ALARMS COMING SUMMER 2021.

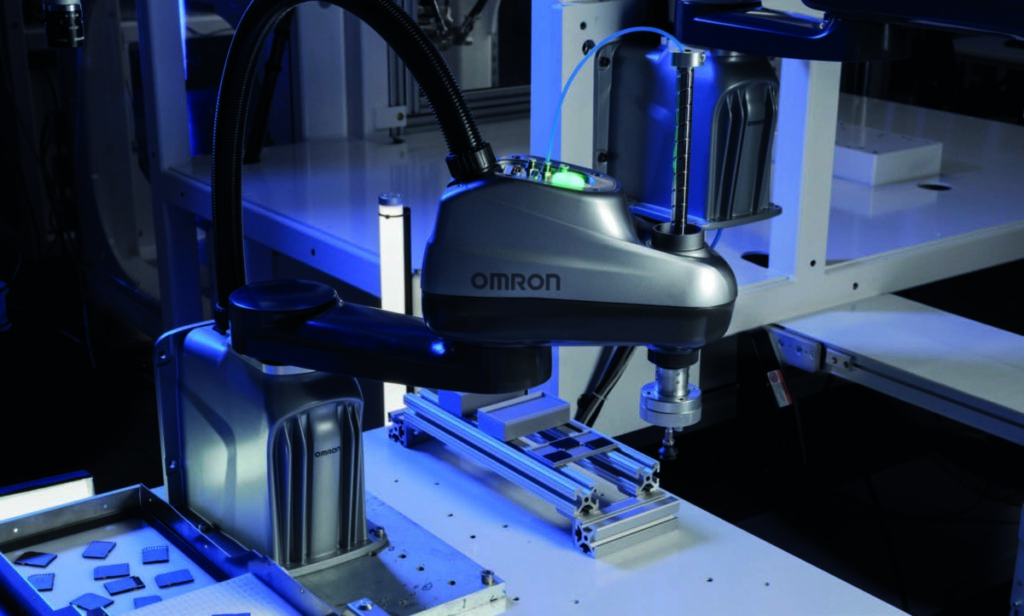

OPTIMAL PERFORMANCE FOR THE LIGHT-DUTY MARKET Advanced performance at the lowest cost of ownership

Gain significantly greater performance for the lowest total cost of ownership. The i4L’s speed, inertia, and repeatability offer advance features providing the best performance necessary for your application.

- Fast cycle time with an unprecedented range of movement and repeatability

- Exceptionally powerful built-in servos to handle payloads with ease

- Advanced and robust industrial design

- Lowest total cost of ownership

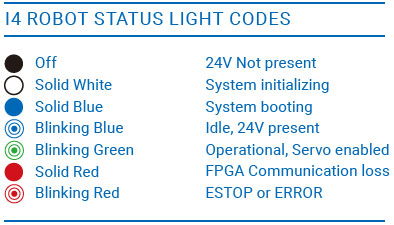

MAXIMIZE UPTIME

Easy to service with interactive maintenance features to prevent accidents and reduce unplanned downtime

The i4L helps you maximize uptime and precision with its interactive maintenance features. The interactive maintenance features are a set of controls which help you monitor your robot with alerts from the RGB dome light and OMRON’s ACE software.

These features help to:

• Reduce unplanned downtime

• Simplify maintenance

• Prevent accidents before they happen

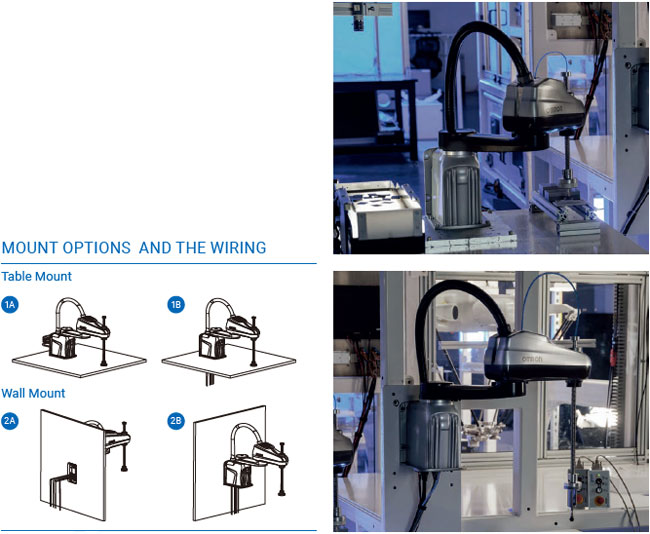

SIMPLE INTEGRATION Get to work faster with simple integration and synchronization

The i4L has a lot of features in this small device.

- Compact and easy to install

- EtherCAT or Ethernet can be connected to the same controller

- i4L has wall or tabletop mounting options

- In addition, the i4L’s Integrated Controller reduces wiring costs

and simplifies installation, as all hardware is integrated into the robot base

AUTOMATE YOUR PRODUCTION LINE WITH OMRON’S i4L

- You can easily program the i4L robot alongside the rest of OMRON’s devices (vision, motion, IO, safety) from OMRON’s single programming software, Sysmac.

- Additionally, OMRON’s Sysmac software is able to simulate your entire production line which reduces troubleshooting time and allows you to achieve very high levels of synchronization between multiple robots or robots and servos, all connected through EtherCAT.