THE OMRON TM COLLABORATIVE ROBOT

HUMAN AND MACHINE IN PERFECT HARMONY

Designed to work with both humans and machines, this robot is the latest in a long line of innovations in automation technology for industrial applications.

Safe and transportable, with built-in vision, this robot allows for quick start-ups and rapid changeovers. Its intuitive software enables the robot to be easily trained to perform almost any task wherever you may need it, freeing your workforce from repetitive tasks and increasing your productivity.

ADAPTABLE TO YOUR NEEDS

Whether you’re working in automotive, semiconductors, secondary packaging for food, or cosmetics, the OMRON TM Collaborative Robot is designed to adapt to almost any industry.

FLEXIBLE FOR YOUR FACTORY

The OMRON TM Collaborative Robot is so versatile it can be assigned to almost any task.

Respond to any manufacturing need by configuring the robot at will, maximizing your resources and increasing productivity.

EASILY SWITCH END-EFFECTORS TO COMPLETE ANY TASK

QUICK START-UP AND CHANGEOVER

INTUITIVE SOFTWARE FOR EASY PROGRAMMING

Downtime costs money, which means you need a robot that can start fast and stay running. Our Plug and Play software enables this robot to work right out of the box.

It is so intuitive it allows for quick programming during startups and changeovers, getting your production up and running as fast as possible.

FASTER SET-UP WITH BUILT-IN VISION

FIVE MEGAPIXEL CAMERA WITH EXCEPTIONAL FIELD OF VISION

The OMRON TM Collaborative Robot features a built-in vision system. The integrated camera localizes objects in a wide field of vision, and the image-enhancement light enables object recognition under almost any conditions.

The vision system improves reliability, consistency, and high-precision placement, and includes functions such as pattern matching, barcode reading, and color classification which enable inspection, measurements and sorting with no additional cost or effort.

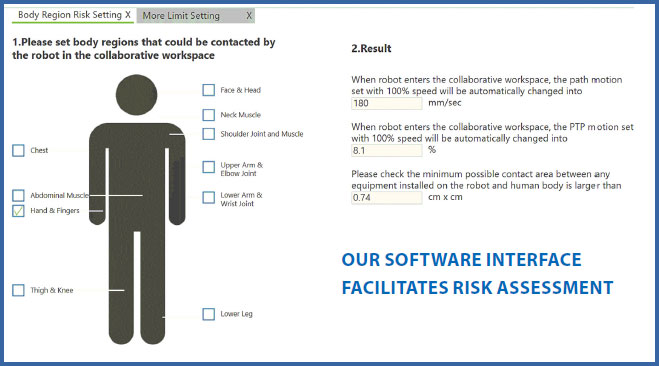

SAFETY

Harmony between humans and machines requires the highest standards of safety. The OMRON TM Collaborative Robot is designed to promote a safer workplace.

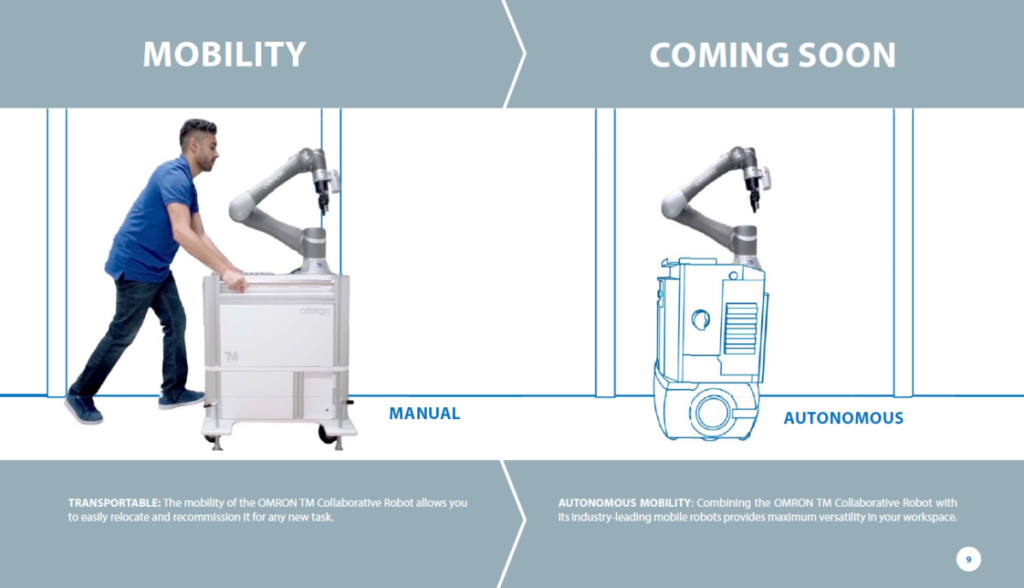

MOBILITY