MACHINING SOLUTIONS

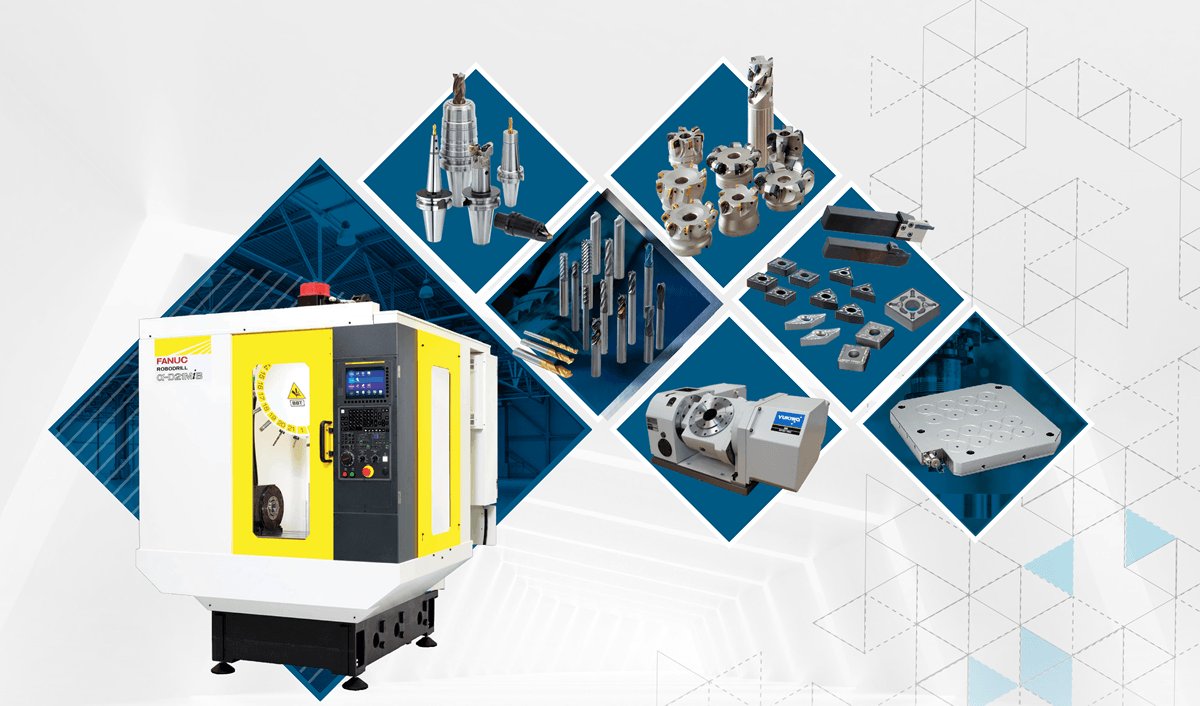

• Advice on optimal selection of CNC machines, cutting tools, tooling systems, jig/fixture, etc

• Design process of machining workpieces according to customers’ requirements

• Machining line diagnosis in terms of cost, line balancing and time study to improve productivity and efficiency

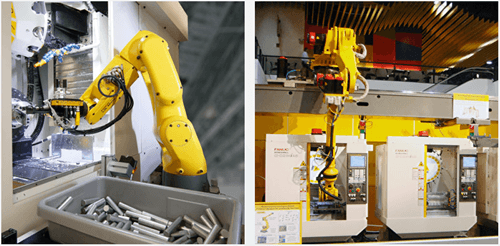

AUTOMATION SOLUTIONS

and software to demonstrate work simulation.

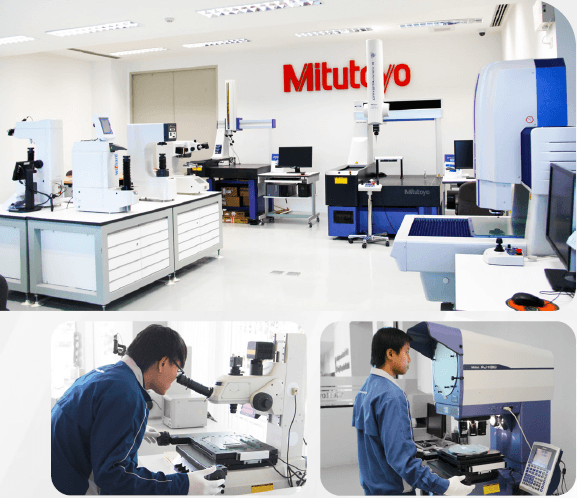

MEASURING SOLUTIONS

• Provide technical advice, training on usage and maintenance, as well as troubleshooting by specialists

• Mitutoyo’s showrooms to demonstrate measurement of customer’s workpieces to facilitate maximum return on investment

• Provide after-sales service, including ISO/IEC 17025 accredited calibration, and advice on software upgrades and accessory options to enhance instrument performance

• Provide advice on measurement data management systems to visualize product quality

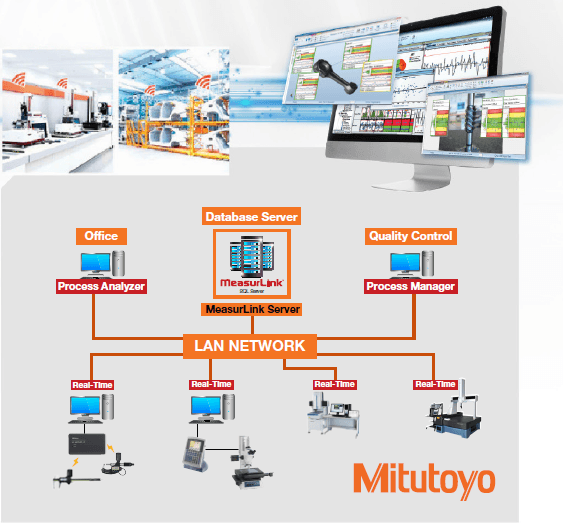

Measurement Data Network System

MeasurLink

Preventive Measures Against Product Scrapping

All data from measuring tools and instruments connected to the network is collected in real time, allowing product failure prediction by implementing statistical process control.

Causal Analyses Enabled with Accumulated Data

Immediate database access to measurement results enables statistical analysis to be applied

for rapid identification of process issues.

Measurement Data Wireless Communication System

U-WAVE

This is a system that transmits data from Mitutoyo Digimatic gages to software such as Excel or Notepad via wireless communication. It saves time and eliminates misinput, helps achieve cost reductions and better efficiency while maintaining excellent operability.