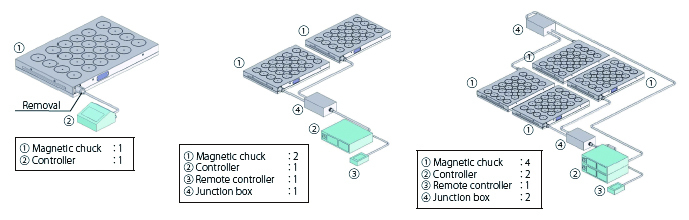

จัดวางฟรีตามพื้นที่ว่างบนโต๊ะเครื่อง

การตัดเฉือนเพิ่มเติมสำหรับหัวจับแม่เหล็กไฟฟ้าแบบถาวรเท่านั้น

- สามารถจิ๊กสั่งทำพิเศษได้โดยการตัดเฉือนเพิ่มเติม

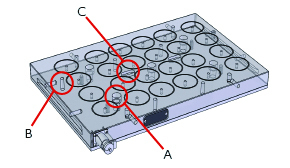

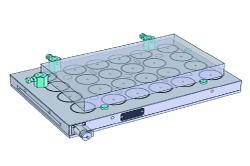

ตัวอย่าง MTB406HD70

- ตัวอย่างเช่น A.เคาน์เตอร์บอร์ B ทะลุรู C. ช่องเสียบกุญแจ เป็นต้น

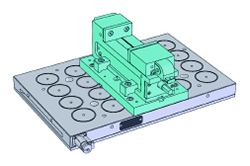

- สำหรับชิ้นงานที่ไม่มีแม่เหล็ก เป็นโต๊ะย่อยสำหรับปากกาจับเครื่องจักร

- สำหรับการผลิตจำนวนมาก เช่น โต๊ะแม่เหล็กสั่งทำพิเศษ

- การใช้องค์ประกอบมาตรฐานและการตัดเฉือนเพิ่มเติม การใช้งานจะกระจายออกไป

- สามารถขอเครื่องจักรเพิ่มเติมได้