แรงดูดซับที่แข็งแกร่ง 6150N

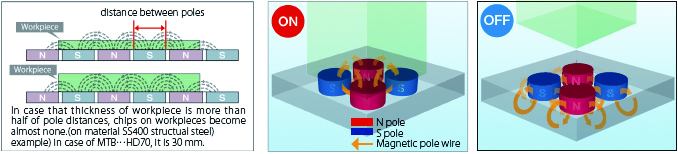

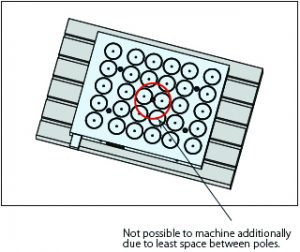

- เศษน้อยที่สุดบนพื้นผิวการทำงาน (ต่อเสาขนาดเส้นผ่านศูนย์กลาง 70 มม. ภายใต้เงื่อนไขสูงสุด)

- แรงขับในการตัดในการกัดไม่อยู่ในทิศทางเดียวกัน ดังนั้นจึงต้องใช้แรงดูดซับที่แข็งแกร่ง ขั้วแม่เหล็กแต่ละขั้วมีแม่เหล็กนีโอไดเมียมที่แข็งแกร่งเพื่อสร้างแรงที่แข็งแกร่ง เนื่องจากสนามแม่เหล็กไหลจากขั้ว N ไปยังขั้ว S ภายในชิ้นงาน จึงทำให้เกิดเศษบนชิ้นงานน้อยที่สุด

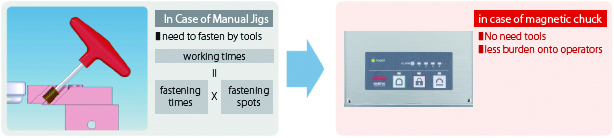

การปรับปรุงประสิทธิภาพการดำเนินงาน

- จิ๊กแบบแมนนวลจำเป็นต้องใช้เครื่องมือ แต่หัวจับแม่เหล็กจะกดปุ่มเท่านั้น

การบูรณาการกระบวนการ

- ไม่มีการรบกวนเครื่องมือตัดที่ถูกหนีบจากด้านล่าง

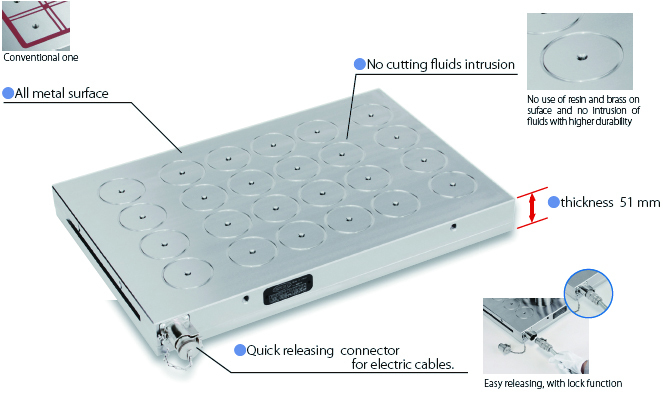

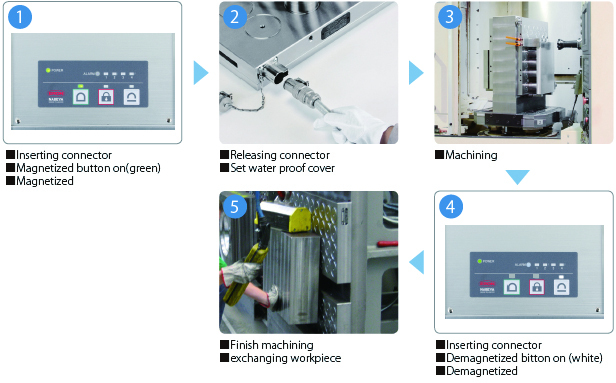

ขั้นตอนการทำงาน (ใช้งานง่าย) ถอดได้เฉพาะปุ่มกดและขั้วต่อเท่านั้น

สั่งทำพิเศษ หัวจับ MTB

- บางครั้ง ไม่สามารถวางหัวจับแม่เหล็กมาตรฐานไว้บนโต๊ะเครื่องจักรได้เนื่องจากรูปทรงโต๊ะไม่ปกติ

- สามารถผลิตหัวจับแม่เหล็กแบบสั่งทำพิเศษสำหรับลูกค้าประเภทนี้ได้

- มาตรฐาน MTB506HD70 / สั่งทำพิเศษ MTB506HD70

ตัวอย่างหัวจับ MTB แบบสั่งทำพิเศษ

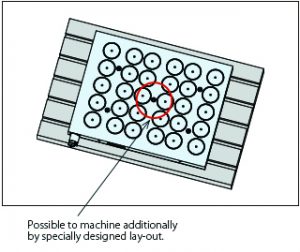

① เปลี่ยนระยะห่างของขั้วแม่เหล็ก

② เปลี่ยนขนาดภายนอก

③ ลบร่องจับยึดทั้งสองด้าน

อาจมีข้อจำกัดบางประการในการสร้างหัวจับแบบสั่งทำพิเศษ