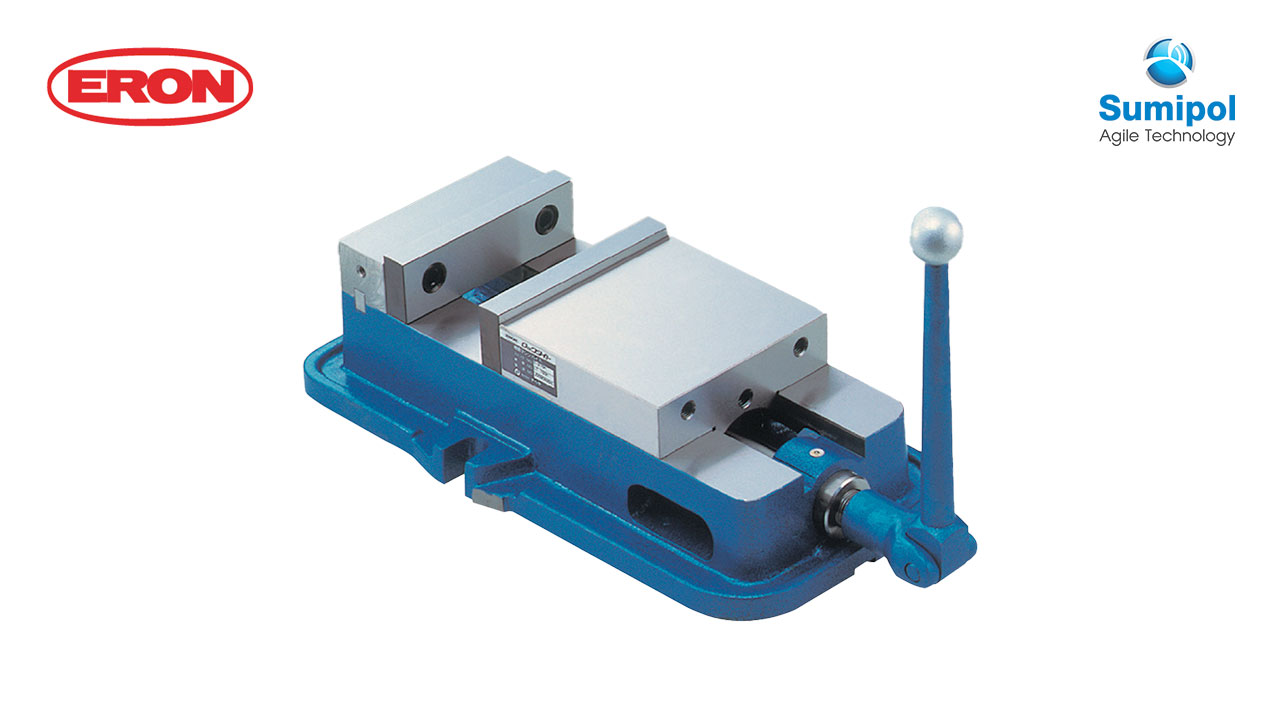

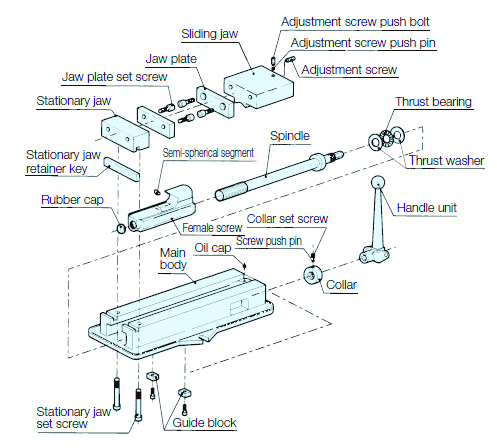

การวาดส่วนที่รื้อถอน

การสั่งซื้อสินค้าแบบขนาน

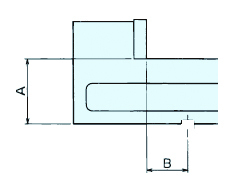

(A และ B สามารถจัดแนวได้ภายใน 0.01 ไม่ว่าจะกี่ชิ้นก็ตาม)

หากคำต่อท้ายหมายเลขการผลิต (ติดกับกล่องด้านนอกและตัวหลัก) เป็นอักษรเดียวกัน ดังนั้น สินค้าจะขนานกันกี่ชิ้นก็ได้ (สำหรับบล็อคนำมาตรฐาน) ไม่มีค่าใช้จ่ายสำหรับผลิตภัณฑ์แบบขนาน

- เมื่อซื้อครั้งแรก

สั่งซื้อผลิตภัณฑ์สเปคที่ตรงกัน (ต่อท้าย G) เมื่อสั่งซื้อให้ระบุความกว้างร่องของเครื่องที่คุณใช้

- หากต้องการสั่งซื้อเพิ่มเติม

ติดต่อเราด้วยตัวอักษรต่อท้ายของหมายเลขการผลิต (ประทับตราบนแผ่นป้ายชื่อ) และความกว้างของไกด์บล็อคของปากกาจับที่คุณมี

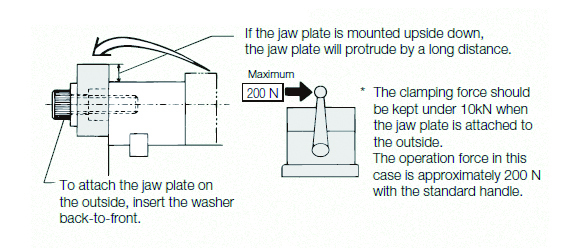

การเพิ่มการเปิดกราม

สามารถเปิดกรามขนาดใหญ่ได้โดยการเปลี่ยนตำแหน่งแผ่นกราม

- การเปิดกรามขึ้นอยู่กับตำแหน่งการติดแผ่นกราม

|

|

|

|

|

| LT100M | 0 – 102 | 48 – 150 | 115 – 217 | 163 – 265 |

| LT125M | 0 – 112 | 56 – 168 | 140 – 252 | 196 – 308 |

| LT150M | 0 – 143 | 63 – 206 | 160 – 303 | 223 – 366 |

| LT200M | 0 – 190 | 85 – 275 | 199 – 389 | 284 – 474 |

| LT250M | 0 – 248 | 110 – 358 | 233 – 501 | 366 – 614 |

- วิธีการเคลื่อนย้ายแผ่นกราม

มาตรฐานความแม่นยำ (ความแม่นยำคงที่)

| No. | Inspection Points (per 100 mm) | Former JIS Standard (O Grade) |

Nabeya SPEC |

| 1 | Parallelism between bottom surface of main body and sliding surface | 0.015 | 0.010 |

| 2 | Perpendicularity between jaw plate and sliding surface (smaller than right angle) | 0.030 | 0.015 |

| 3 | Perpendicularity between T-slot and jaw plate surface of stationary jaw side. | 0.015 | 0.010 |

| 4 | Parallelism between T-slot and jaw plate surface of stationary jaw side. | 0.015 | 0.010 |

| 5 | Parallelism between bottom surface of rotating table and sliding surface | 0.020 | 0.015 |

| 6 | Parallelism between the bottom surface and top surface of the rotating table | – | 0.010 |

| (Clamping Accuracy) | |||

| 7 | Parallelism between top surface of clamped test block and bottom surface of main body | 0.020 | 0.015 |

| 8 | Parallelism between top surface of clamped test block and bottom surface of rotating table | 0.030 | 0.020 |

| 9 | Lift-up of top surface of test block when clamped | 0.030 | 0.015 |