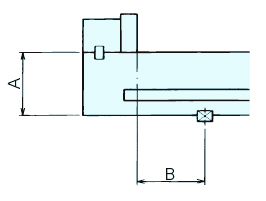

การสั่งผลิตภัณฑ์แบบขนาน

(A และ B สามารถจัดแนวได้ภายใน 0.01 ไม่ว่าจะกี่ชิ้นก็ตาม)

หากคำต่อท้ายหมายเลขการผลิต (ติดกับกล่องด้านนอกและตัวหลัก) เป็นตัวอักษรเดียวกัน สินค้าจะขนานกันไม่ว่าจะกี่ชิ้นก็ตาม ไม่มีค่าใช้จ่ายสำหรับผลิตภัณฑ์แบบขนาน

- เมื่อซื้อเป็นครั้งแรก สั่งซื้อผลิตภัณฑ์สเปคที่ตรงกัน (ต่อท้าย G) เมื่อสั่งซื้อ ให้ระบุความกว้างร่องของเครื่องที่คุณใช้

- สำหรับการสั่งซื้อเพิ่มเติม โปรดติดต่อเราพร้อมระบุหมายเลขการผลิตต่อท้าย (ประทับตราบนแผ่นป้ายชื่อ) และความกว้างของบล็อคนำของปากกาจับที่คุณมี

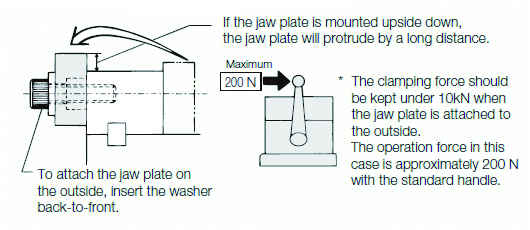

การเพิ่มการเปิดกราม

สามารถรับช่องเปิดของขากรรไกรขนาดใหญ่ได้โดยการเปลี่ยนตำแหน่งแผ่นขากรรไกร

- การเปิดกรามขึ้นอยู่กับตำแหน่งการติดแผ่นกราม

|

|

|

|

|

| LT100MC | 0 – 102 | 48 – 150 | 115 – 217 | 163 – 265 |

| LT150MC | 0 – 143 | 63 – 206 | 160 – 303 | 223 – 366 |

- วิธีการเคลื่อนย้ายแผ่นกราม

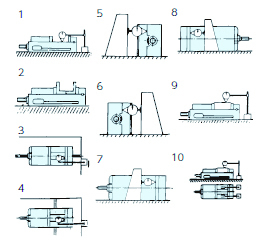

มาตรฐานความแม่นยำ (ความแม่นยำคงที่)

| ลำดับ | จุดตรวจสอบ (ต่อ 100 มม.) | Former JIS Standard (O Grade) |

Nabeya SPEC |

| 1 | ความขนานระหว่าง พื้นผิว ด้านล่างของ ตัวเครื่อง หลักและ พื้นผิว เลื่อน | 0.015 | 0.010 |

| 2 | ความตั้งฉากระหว่างแผ่นกรามและพื้นผิวเลื่อน (เล็กกว่ามุมขวา) | 0.030 | 0.015 |

| 3 | ความตั้งฉากระหว่าง T-slot และพื้นผิวแผ่นขากรรไกรของด้านกรามที่อยู่นิ่ง | 0.015 | 0.010 |

| 4 | ความขนานระหว่าง T-slot และพื้นผิวแผ่นกรามของด้านกรามที่อยู่นิ่ง | 0.015 | 0.010 |

| 5 | ความตั้งฉากระหว่างพื้นผิวด้านข้างของตัวเครื่องหลักและพื้นผิวเลื่อน | – | 0.030 |

| 6 | ความตั้งฉากระหว่างพื้นผิวด้านข้างของตัวเครื่องหลักและพื้นผิวเลื่อน | – | 0.030 |

| 7 | ความตั้งฉากระหว่างพื้นผิวด้านข้างของตัวเครื่องกับพื้นผิวแผ่นกรามของด้านกรามที่อยู่นิ่ง | – | 0.050 |

| 8 | ความตั้งฉากระหว่างพื้นผิวด้านข้างของตัวเครื่องกับพื้นผิวแผ่นกรามของด้านกรามที่อยู่นิ่ง | – | 0.050 |

| (ความแม่นยำในการจับยึด) | |||

| 9 | ความขนานระหว่างพื้นผิวด้านบนของบล็อกทดสอบแบบจับยึดและพื้นผิวด้านล่างของตัวเครื่อง | 0.020 | 0.015 |

| 10 | การยกพื้นผิวด้านบนของบล็อกทดสอบขึ้นเมื่อถูกยึด | 0.030 | 0.015 |

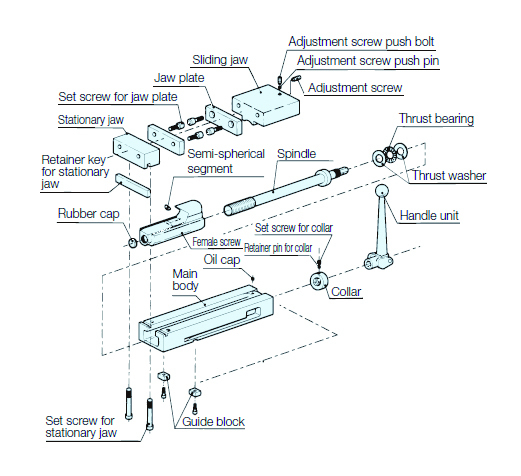

Parts details